Odoo 18 introduces several powerful enhancements to the Manufacturing application, designed to streamline and simplify production management across various warehouse configurations. Whether your business operates with a basic production workflow or a more complex multi-step process, Odoo provides flexible options to meet your operational needs.

In this blog, we’ll focus on the One-Step Manufacturing process, which is particularly well-suited for businesses that require a fast and straightforward flow from raw materials to finished goods without the complexity of multiple stock movements.

Odoo’s manufacturing system supports three levels of operation: one-step, two-step, and three-step manufacturing. When using the One-Step configuration, Odoo allows users to create a Manufacturing Order (MO) that handles everything internally, without generating separate inventory transfers for:

* Moving raw materials out of stock

* Receiving finished goods into inventory

This means that the consumption of components and the production of finished products are handled in a single transaction, simplifying the overall workflow while maintaining full traceability and cost tracking.

In the sections that follow, we’ll guide you through a complete example of setting up and executing a One-Step manufacturing flow in Odoo 18, including:

* Creating a manufacturable product

* Defining the Bill of Materials (BoM)

* Configuring operations and work centers

* Executing the production

* Tracking stock movements

* Reviewing cost structure and journal entries

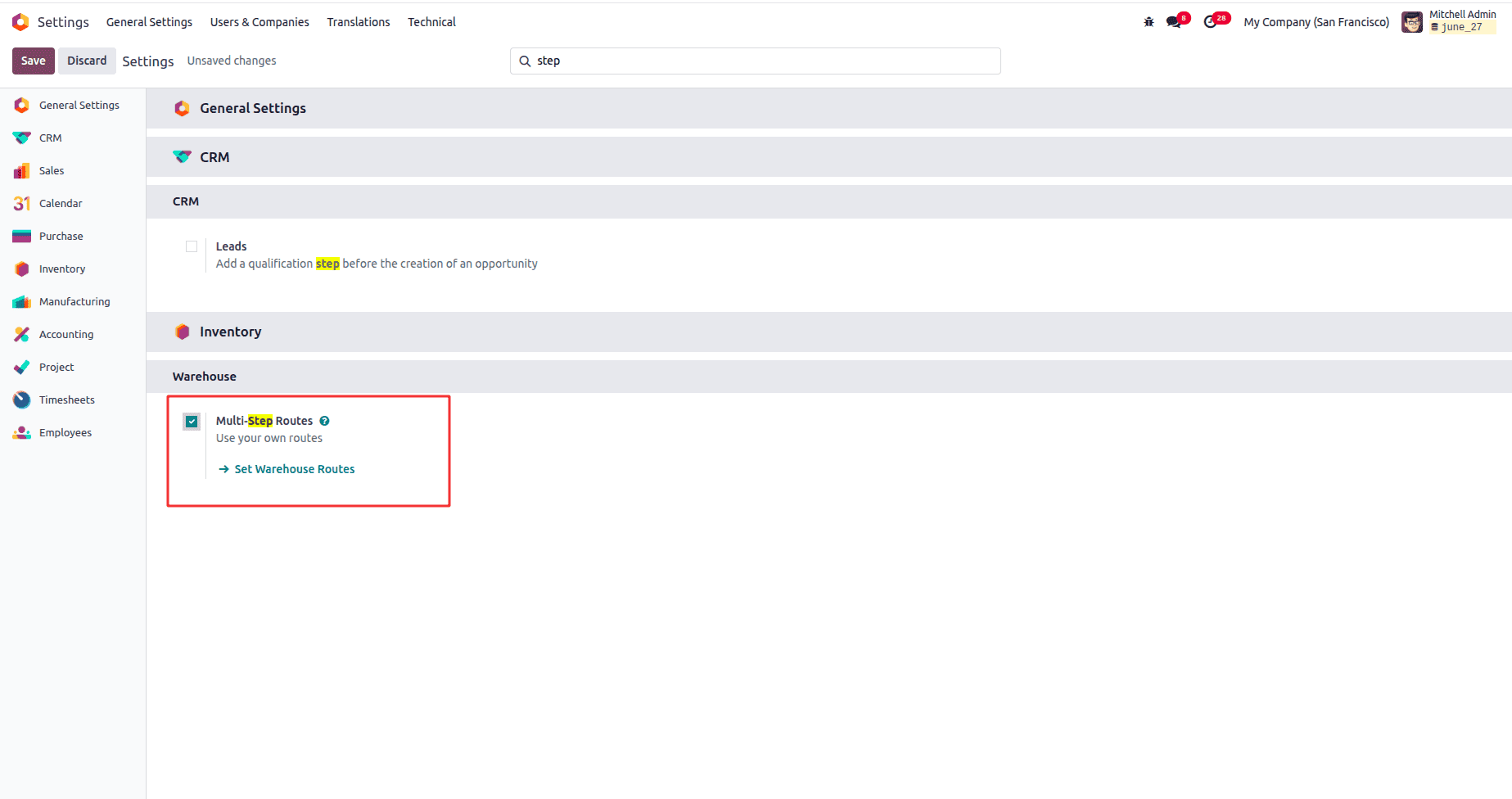

First, enable Developer Mode, then go to Inventory > Settings and activate the Multi-Step Routes option.

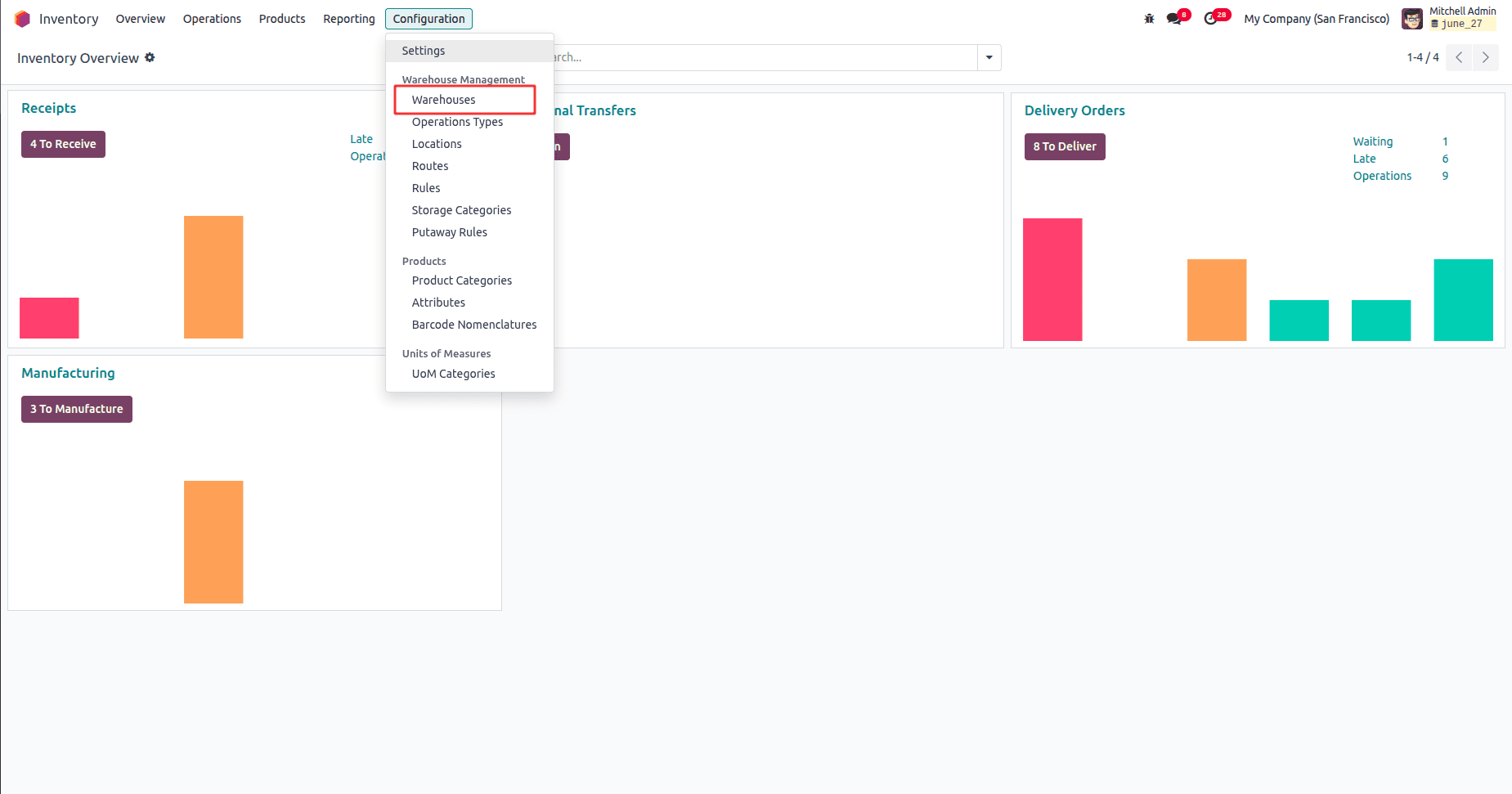

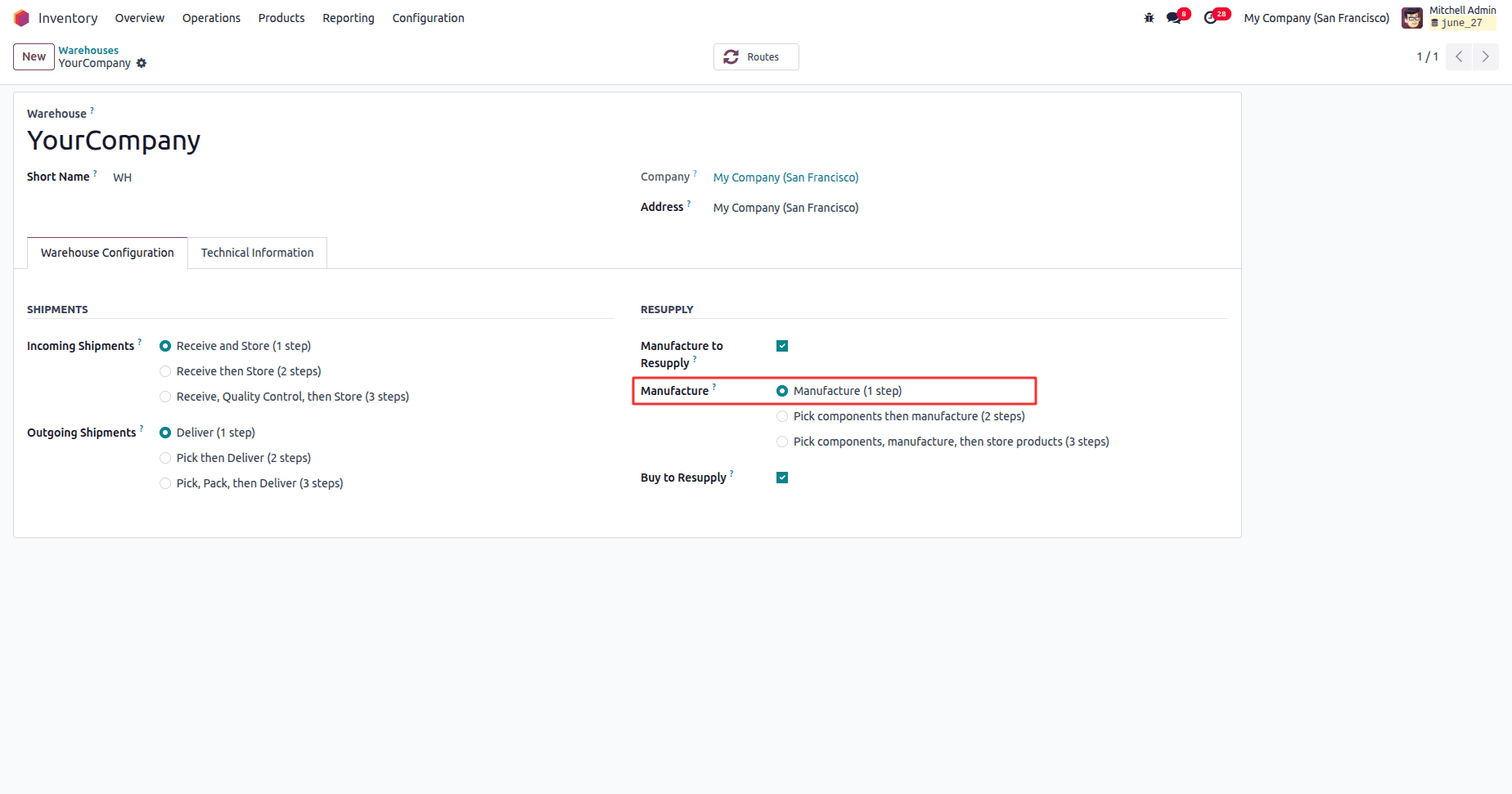

Once Multi-Step Routes are enabled, the next step is to configure your warehouse to support the one-step manufacturing flow. To do this, navigate to Inventory > Configuration > Warehouses, select your warehouse, and scroll down to the Manufacturing section.

In a one-step manufacturing flow, components are consumed and the finished product is produced in a single operation, without the need for separate picking or staging, making it ideal for simple or low-volume production environments. So, enable the Manufacture (1 step) in the manufacture section.

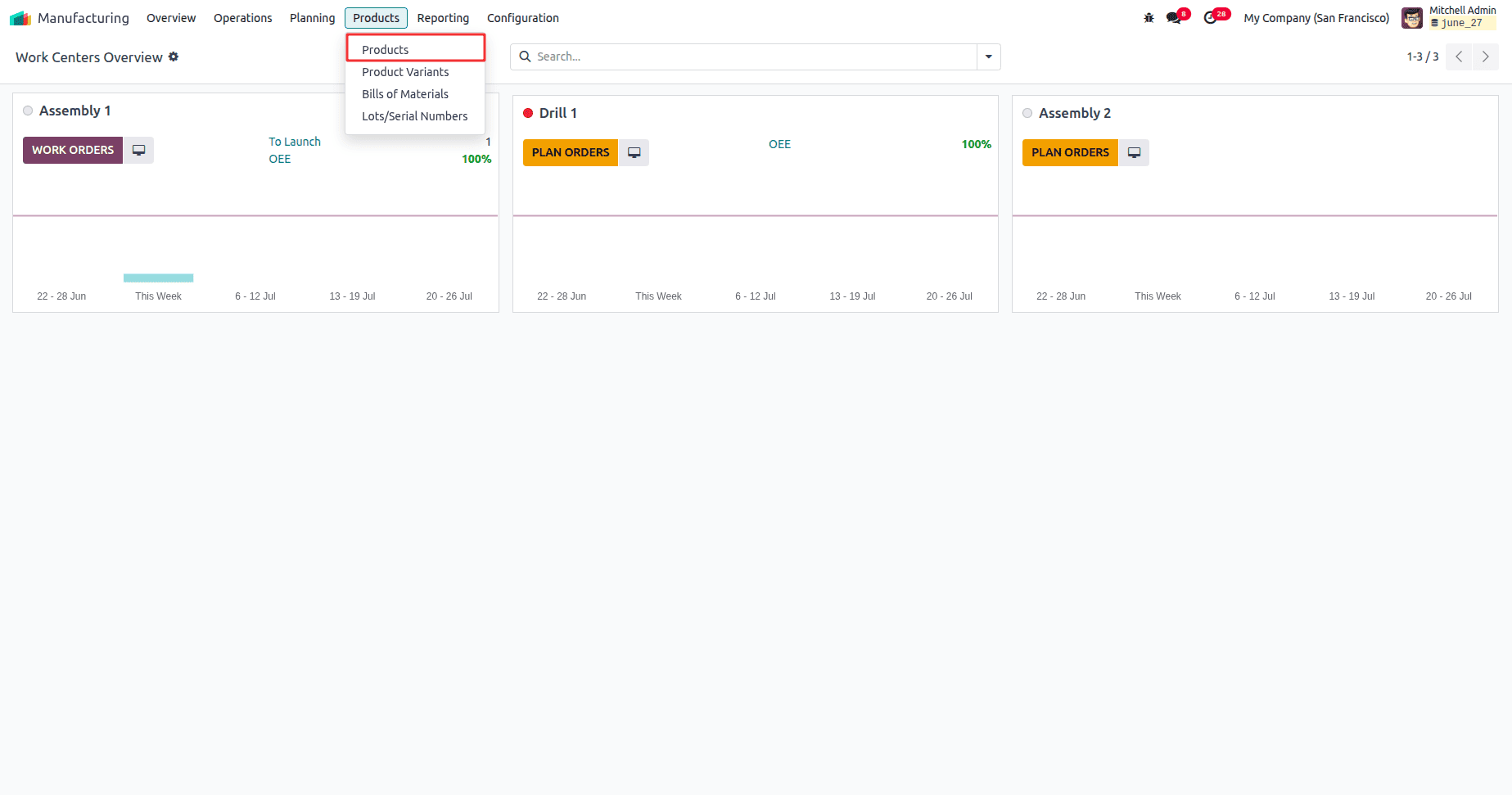

To define a product for manufacturing, navigate to the Manufacturing module and go to Products > Products.

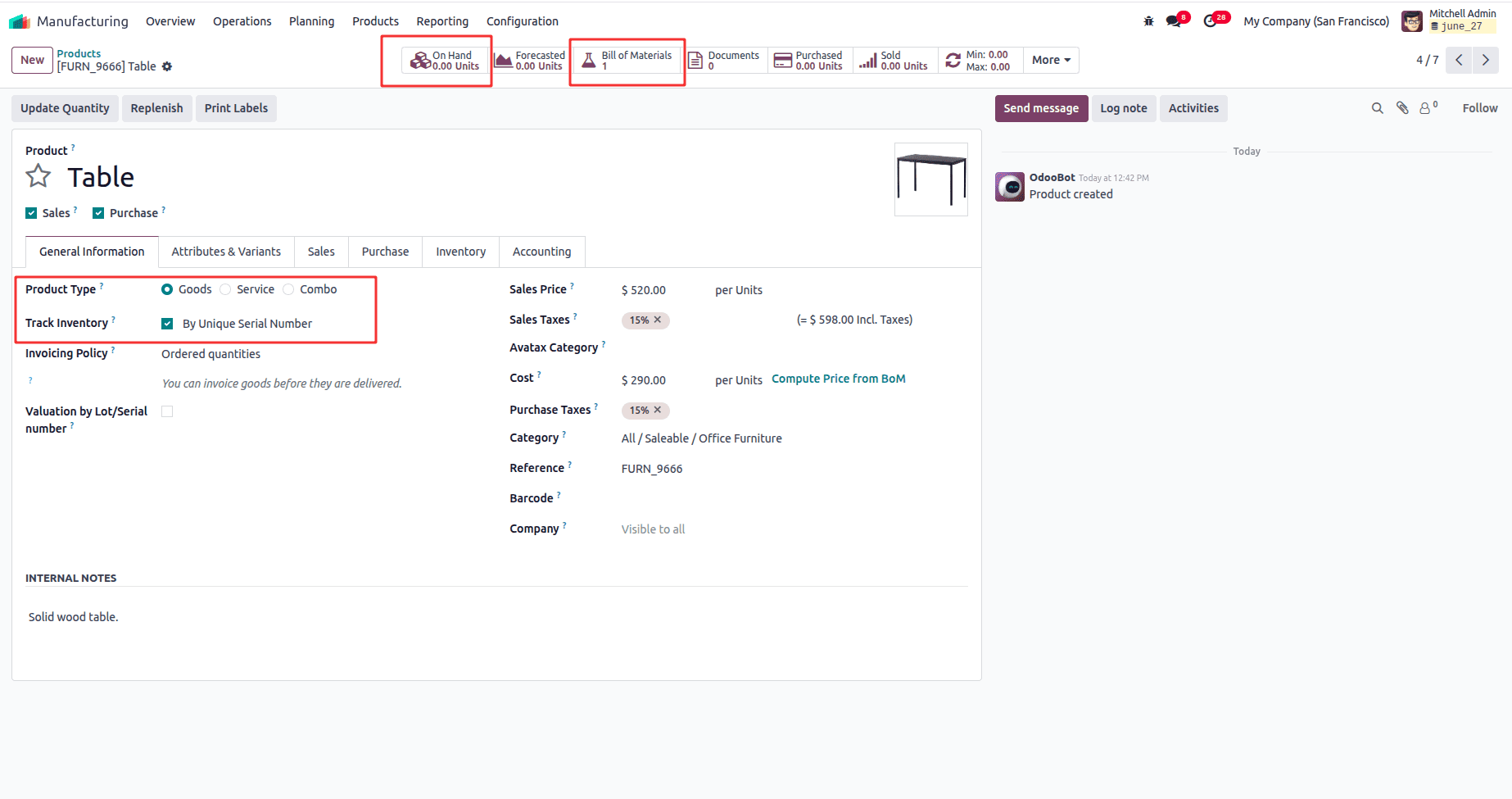

Here we chose Table as the product.

* The product type is set to "goods," meaning it is a tangible item that will be stocked and physically moved. This is essential for manufacturing and inventory tracking operations.

* Inventory tracking is set to "By Unique Serial Number", enabling:

a. Individual tracking of each unit is produced.

b. Traceability throughout the supply chain.

c. Use of serial numbers during production, delivery, and returns.

* Showing on-hand quantity zero indicates that there is no current stock available for this product.

* A Bill of Materials has been defined for this product.

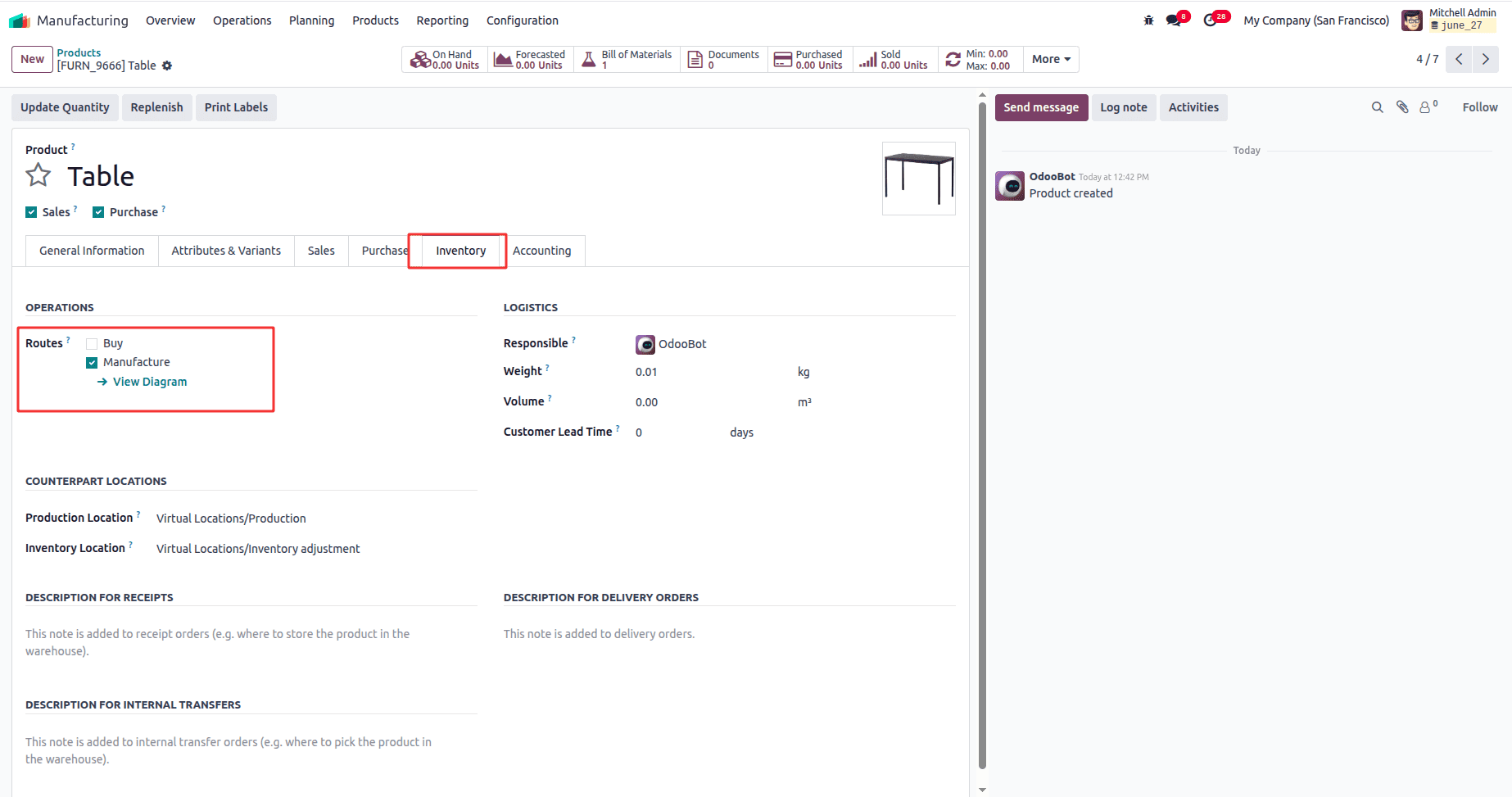

Under the Inventory tab of the product, the route should be set to "Manufacture" to indicate that the product will be produced through a manufacturing process.

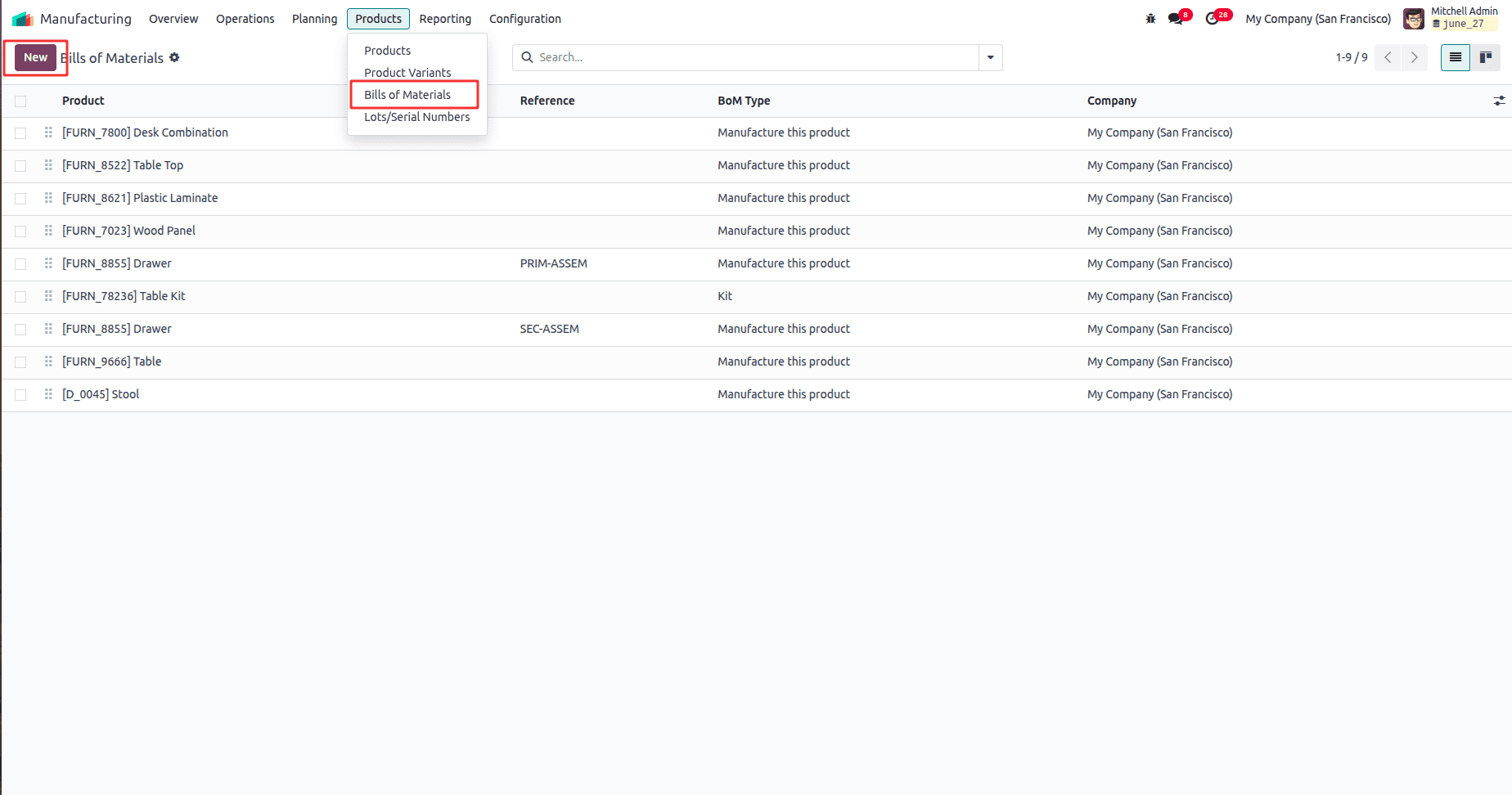

Once the product is created, the next step is to configure its Bill of Materials (BoM), which specifies all the raw materials and components needed for manufacturing. In Odoo 18, you can create a BoM by navigating to Manufacturing > Products > Bill of Materials and clicking on the "New" Button.

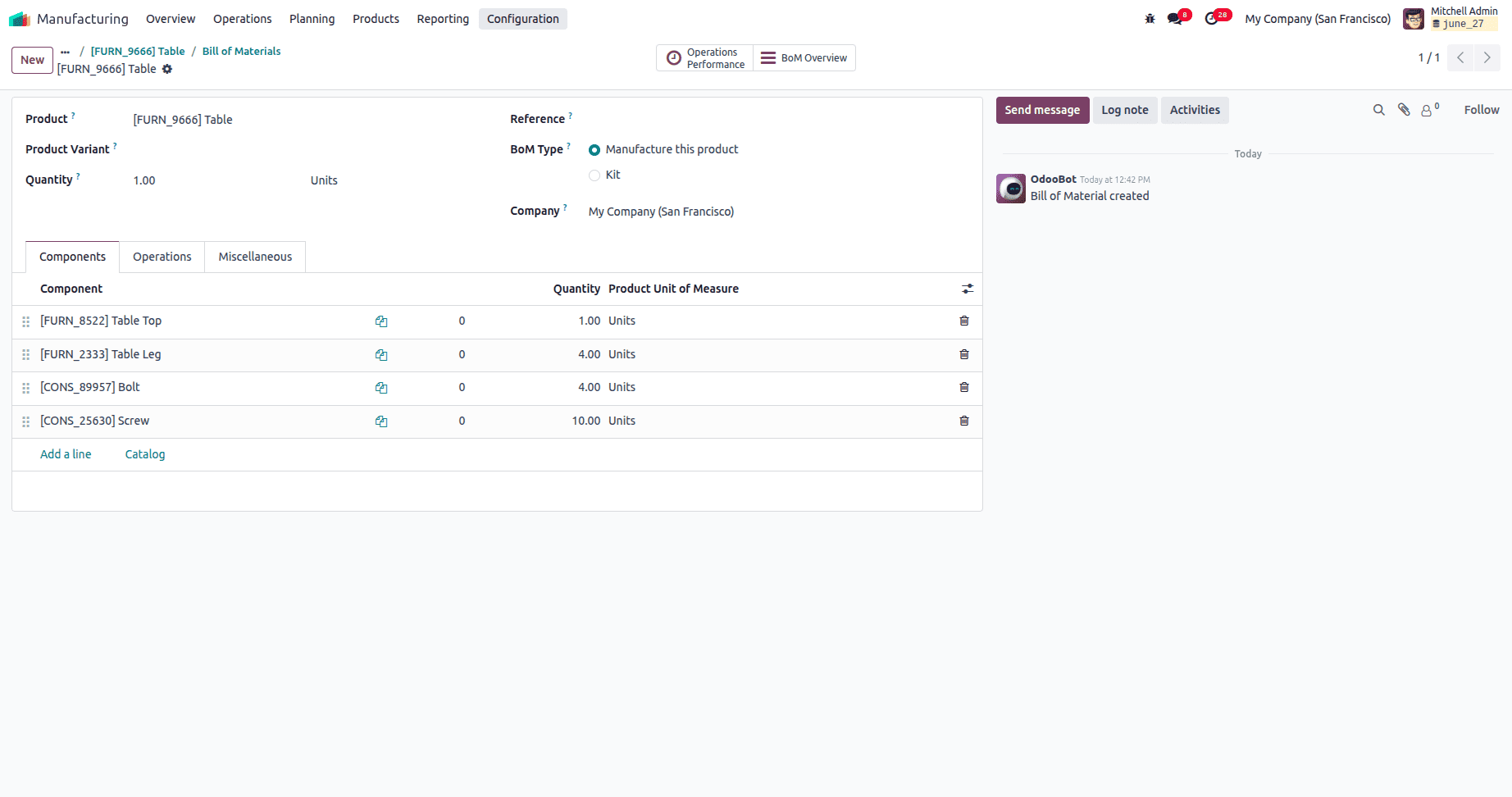

This screenshot shows the Bill of Materials (BoM) configuration for a product named Table, listing the required components, such as tabletop, legs, bolts, and screws, along with their quantities, all needed to manufacture one unit of the finished product.

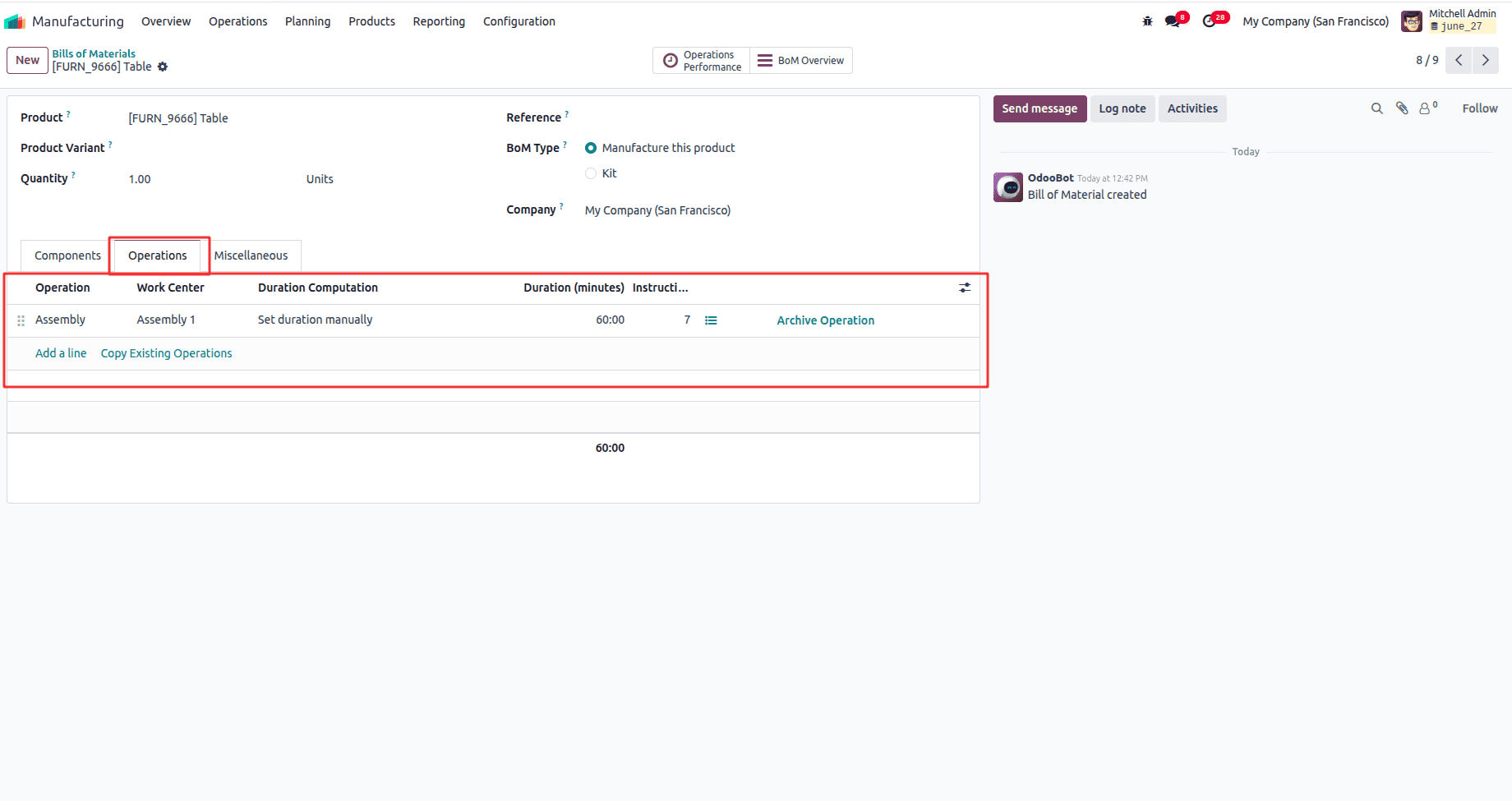

Under the operations tab, we can specify each operation required for the manufacturing of the product. These operations help Odoo plan, schedule, and track time and cost.

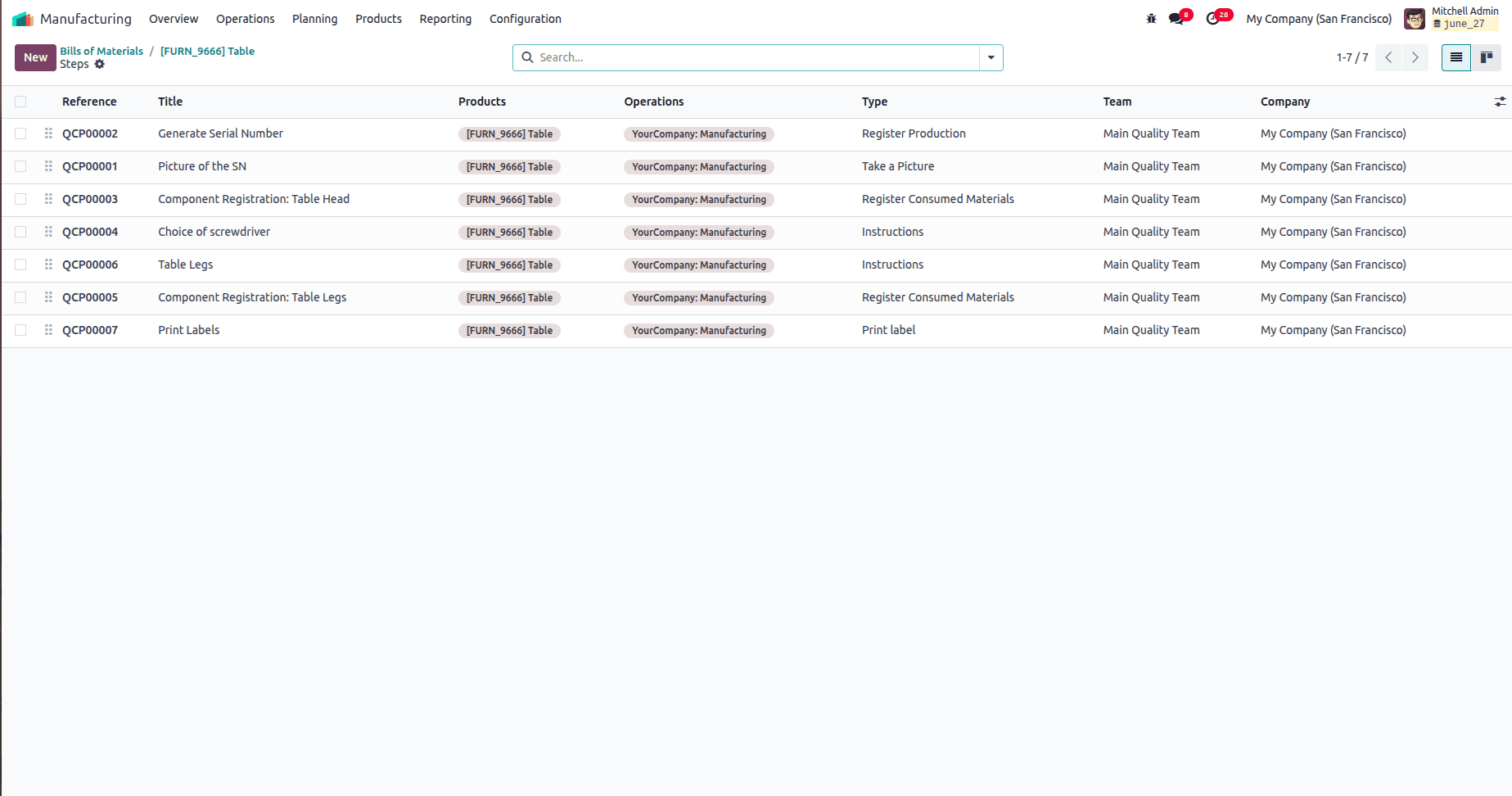

In this configuration, the operation titled “Assembly” is defined as a key step in the manufacturing process and is assigned to the “Assembly 1” work center, where the task will physically take place. The duration computation is set to manual, allowing planners to specify an exact time requirement—in this case, 60 minutes—for completing the task. This setup ensures that when a manufacturing order is created, Odoo will automatically schedule the operation within the selected work center, allocate its capacity accordingly, and factor the time and cost into overall production costing and planning.

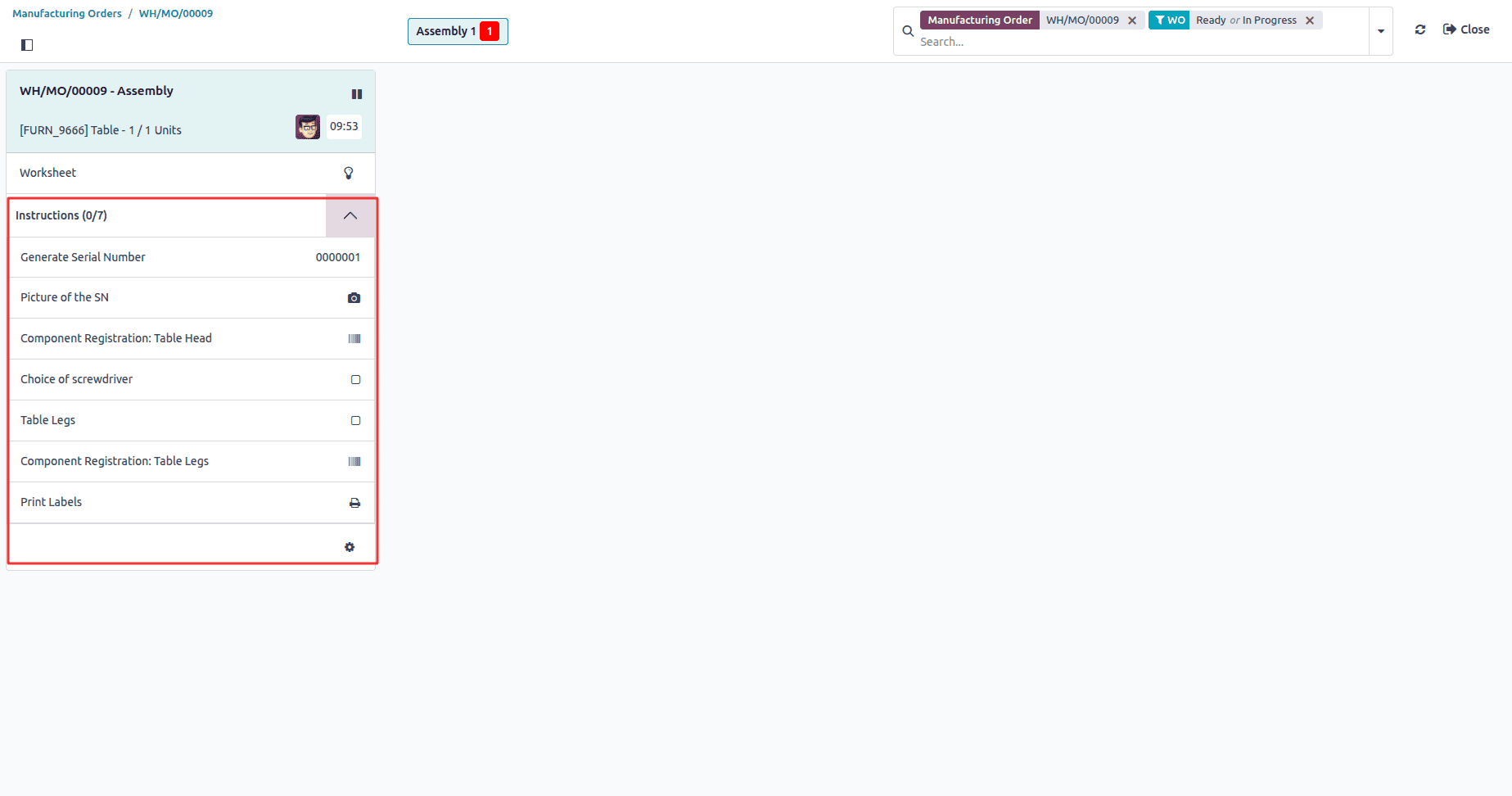

Additionally, the operation includes seven detailed instructions, which can be work instructions, safety guidelines, or visual aids designed to assist production workers in completing the task accurately. These instructions are displayed during the execution of the work order—either in the Work Orders interface or through the Shop Floor module—ensuring consistency, quality, and operational clarity.

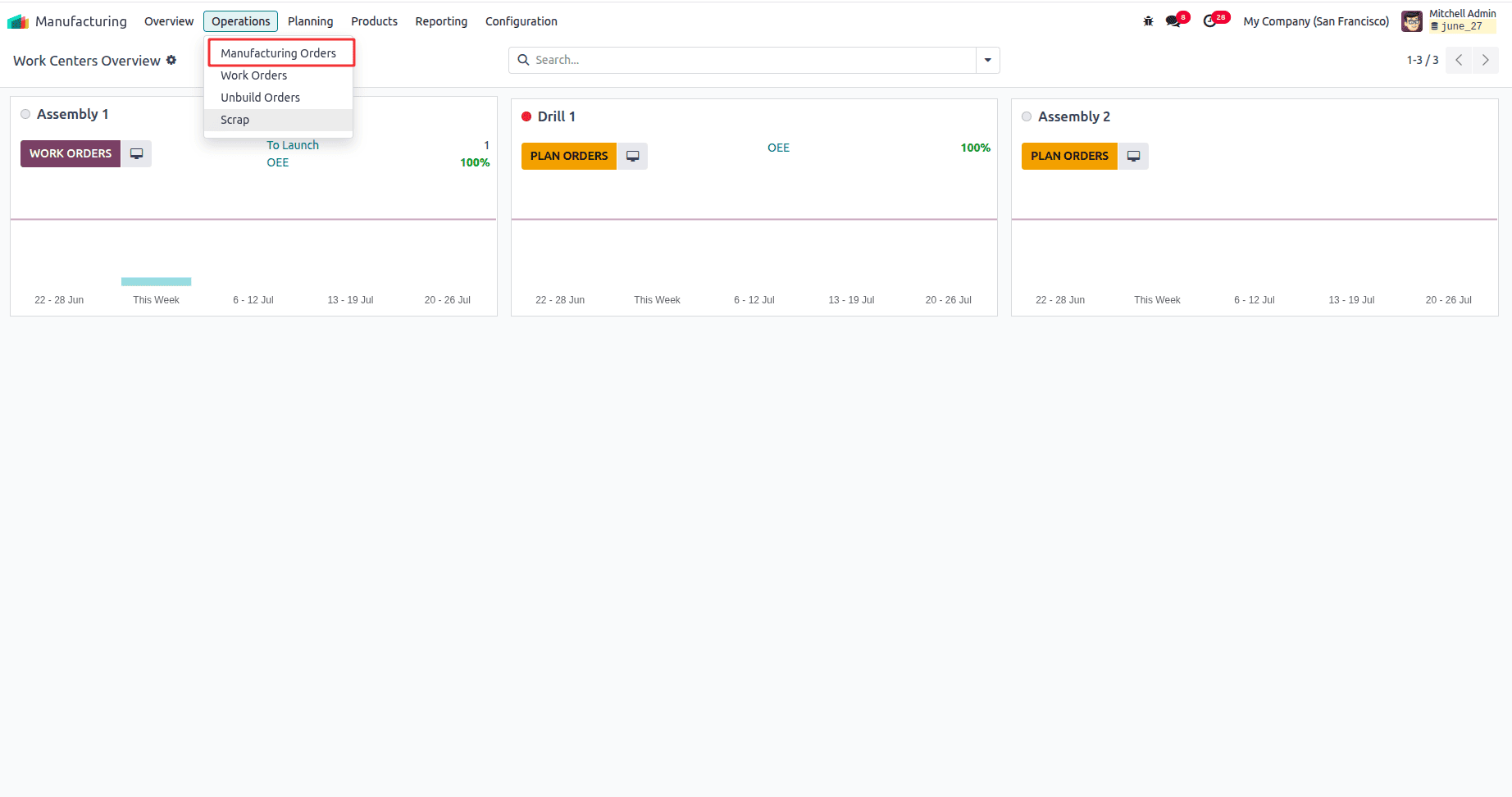

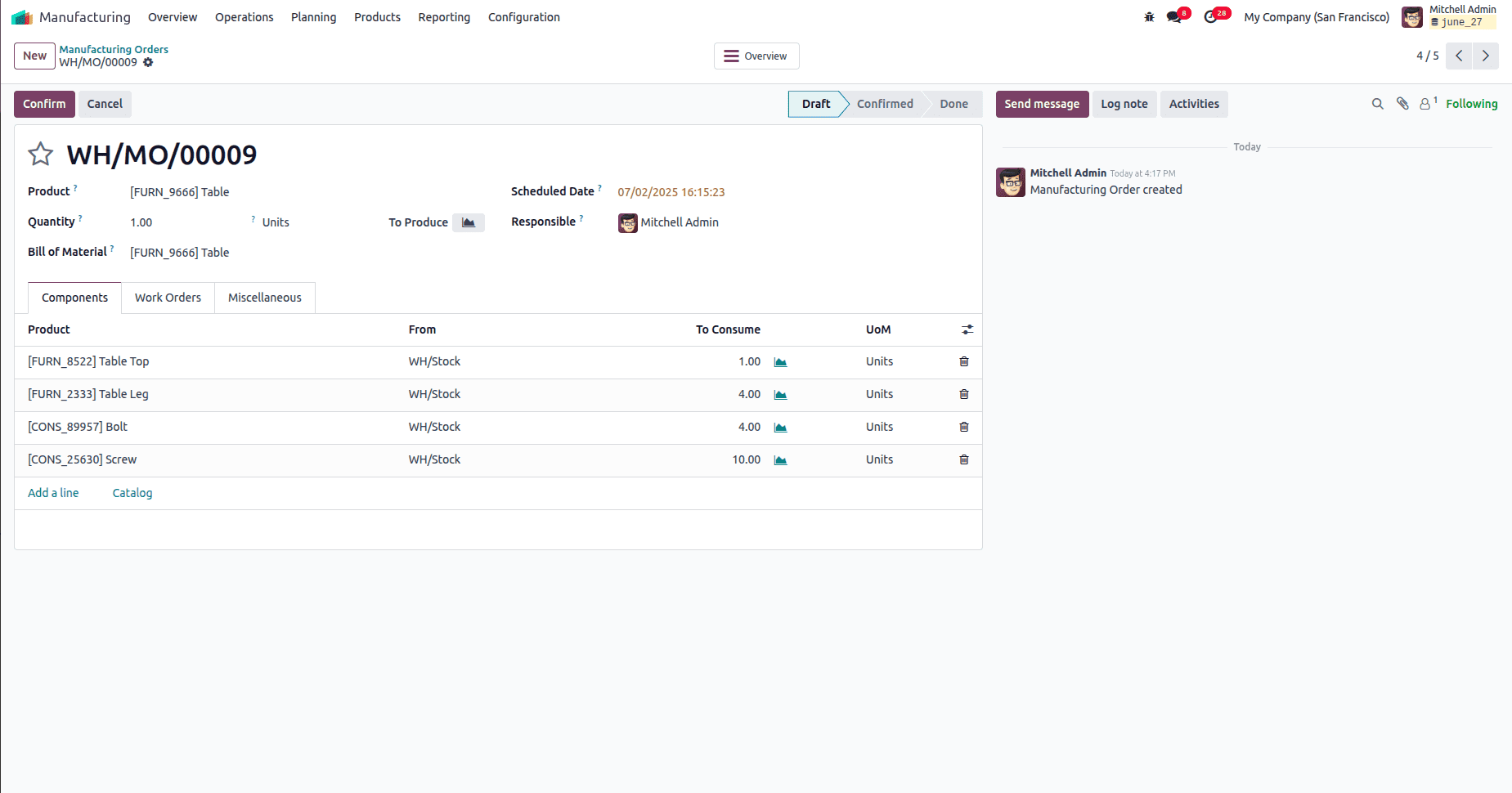

After setting up your product, components, Bill of Materials (BoM), work centers, and operations, you can initiate the production process by creating a Manufacturing Order (MO). To do this, navigate to Manufacturing > Operations > Manufacturing Orders and click on the "New" button

Currently, this will be in the draft stage.

By selecting the product name and the Bill of Materials (BoM), Odoo automatically populates all predefined values associated with that product, including the components and work orders.

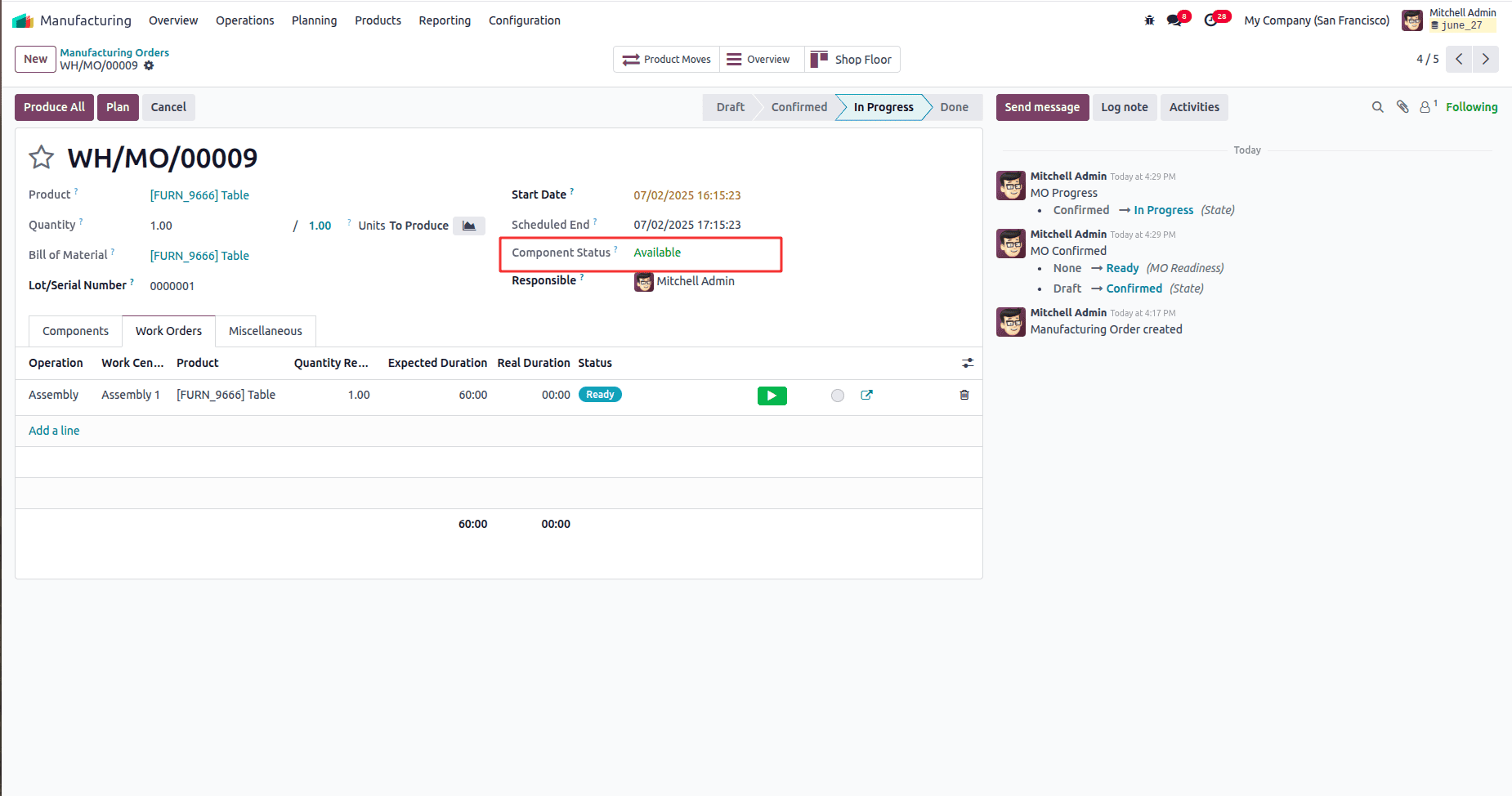

Once the Manufacturing Order (MO) is confirmed, the component status becomes visible, and the associated work orders are updated to 'Ready' status, indicating they are prepared for execution.

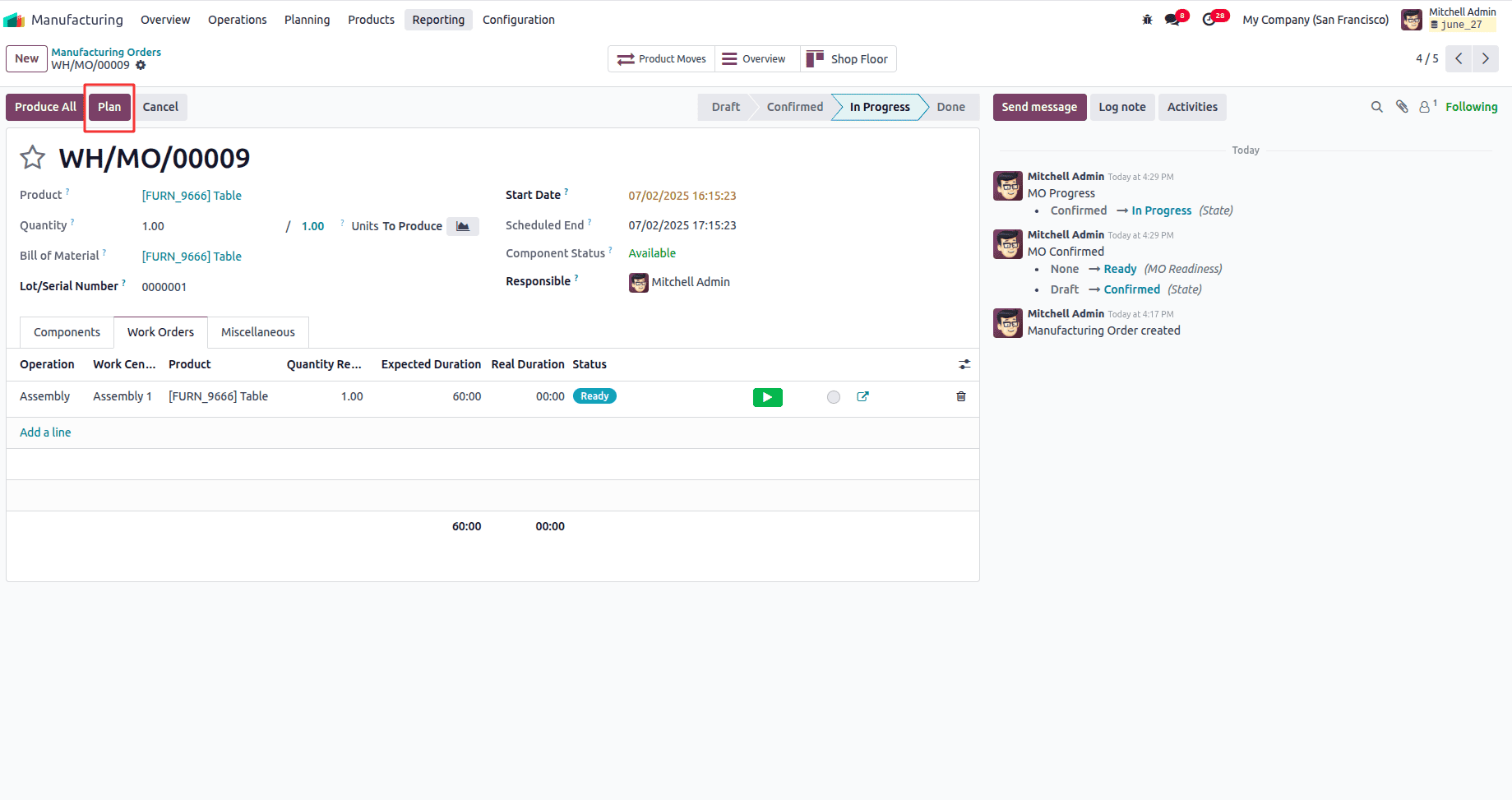

The Plan button activates and schedules the work order(s) linked to the Manufacturing Order (MO), transitioning their status to "Ready," so production can begin.

When the Plan button is clicked, the work orders are scheduled in their assigned work centers, the system verifies that all required components are available, and the Manufacturing Order status changes from Confirmed to In Progress, allowing operators to begin, pause, or complete operations either through the Shop Floor interface or directly within the MO.

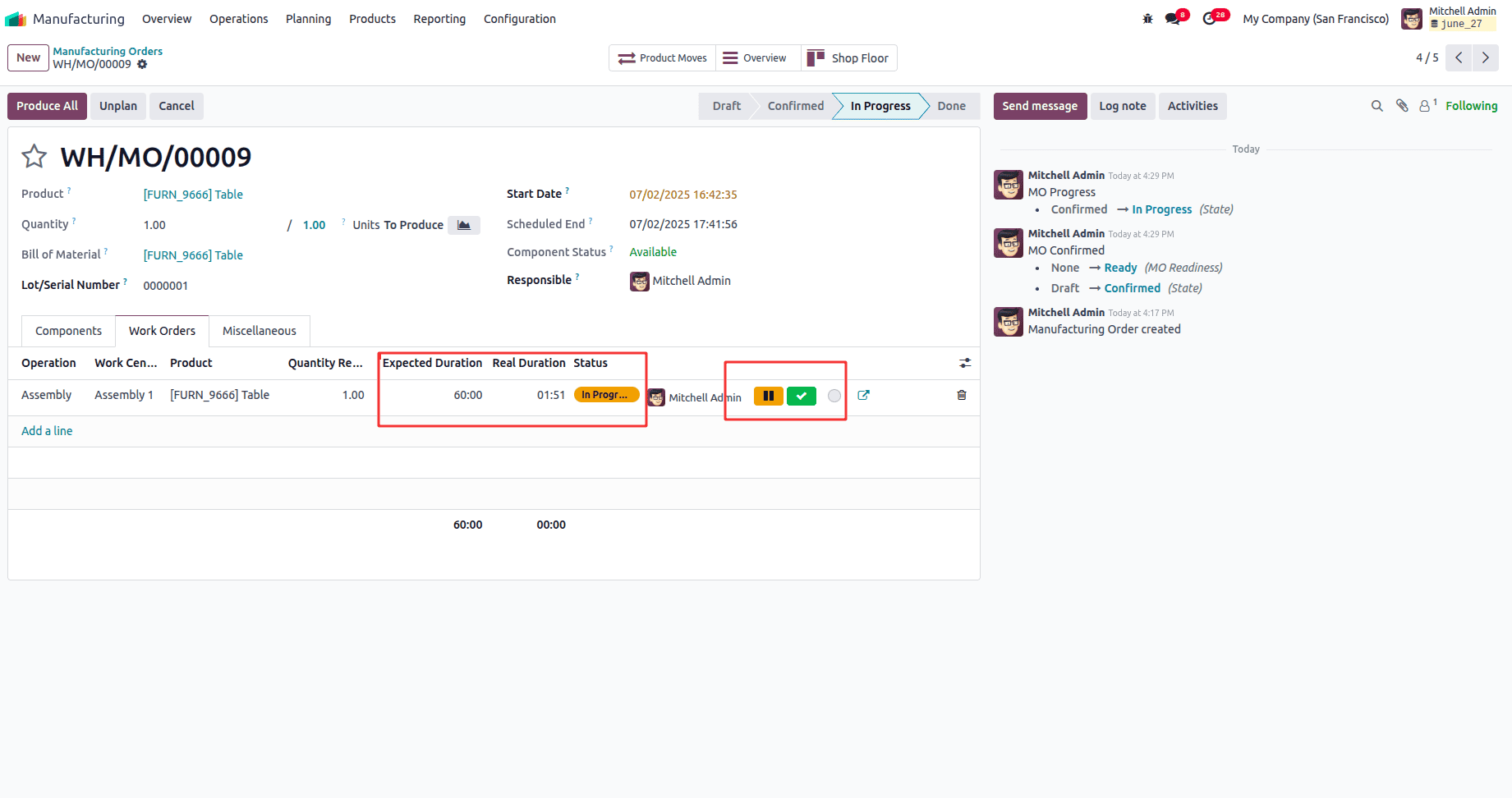

The Start button begins the selected work order operation, allowing Odoo to start tracking real-time duration, resource usage, and progress for that specific task.

By clicking the Pause button, the operation is temporarily halted without being completed—useful in cases such as equipment issues, breaks, or material shortages—as it freezes the real-time duration until resumed.

Clicking the Done button finalizes the work order once the operation is completed; this action stops time tracking, updates the manufacturing order’s progress, and moves the process forward to transferring the finished goods into stock.

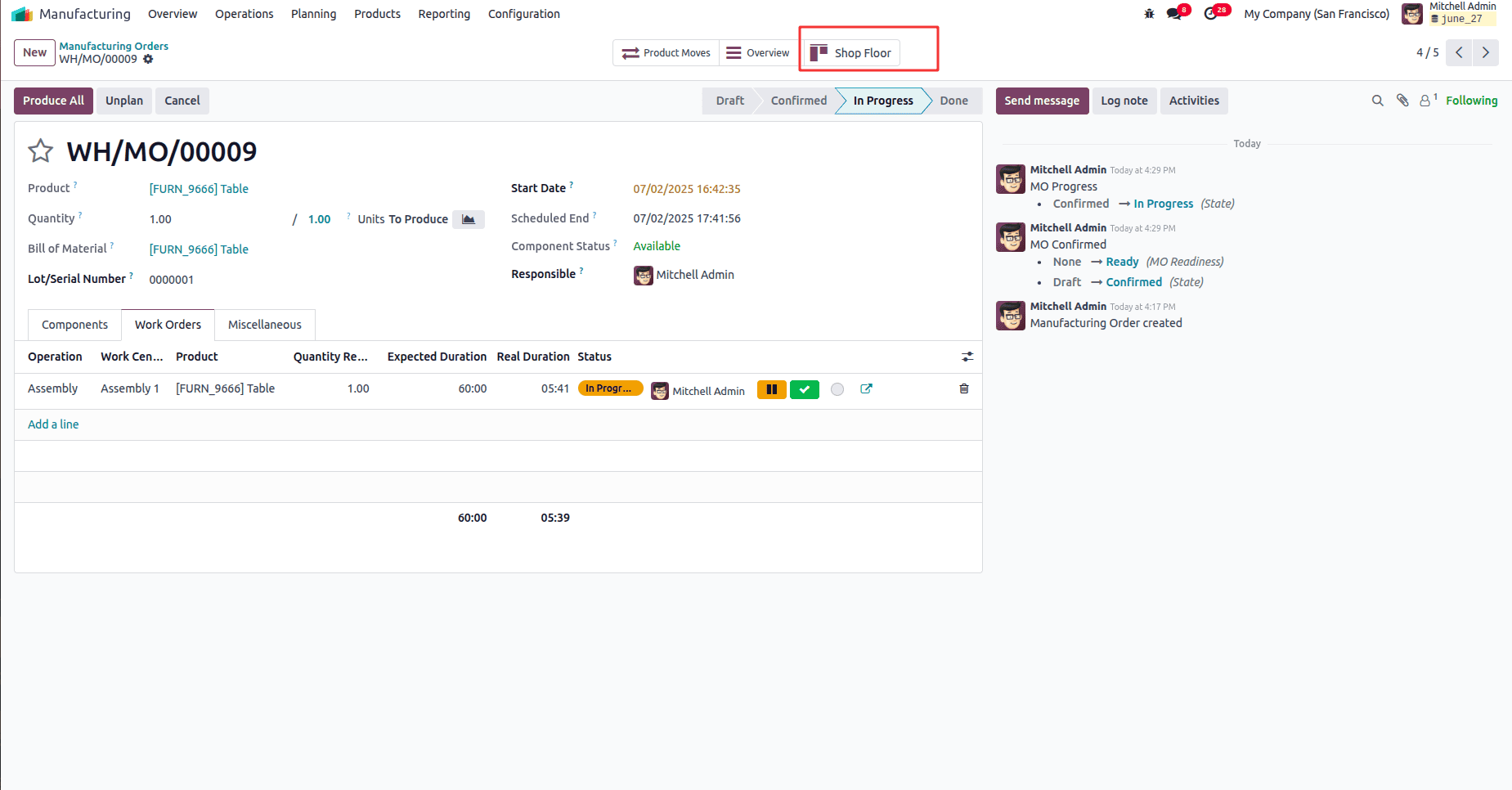

The Shop Floor view allows operators and production staff to start, pause, complete, and manage manufacturing operations directly at their workstation, without needing access to the backend interface.

The Shop Floor module is ideal for production lines where operators need a simplified and guided interface to interact with Odoo, making it especially valuable for manufacturers aiming to digitize and streamline production monitoring and execution.

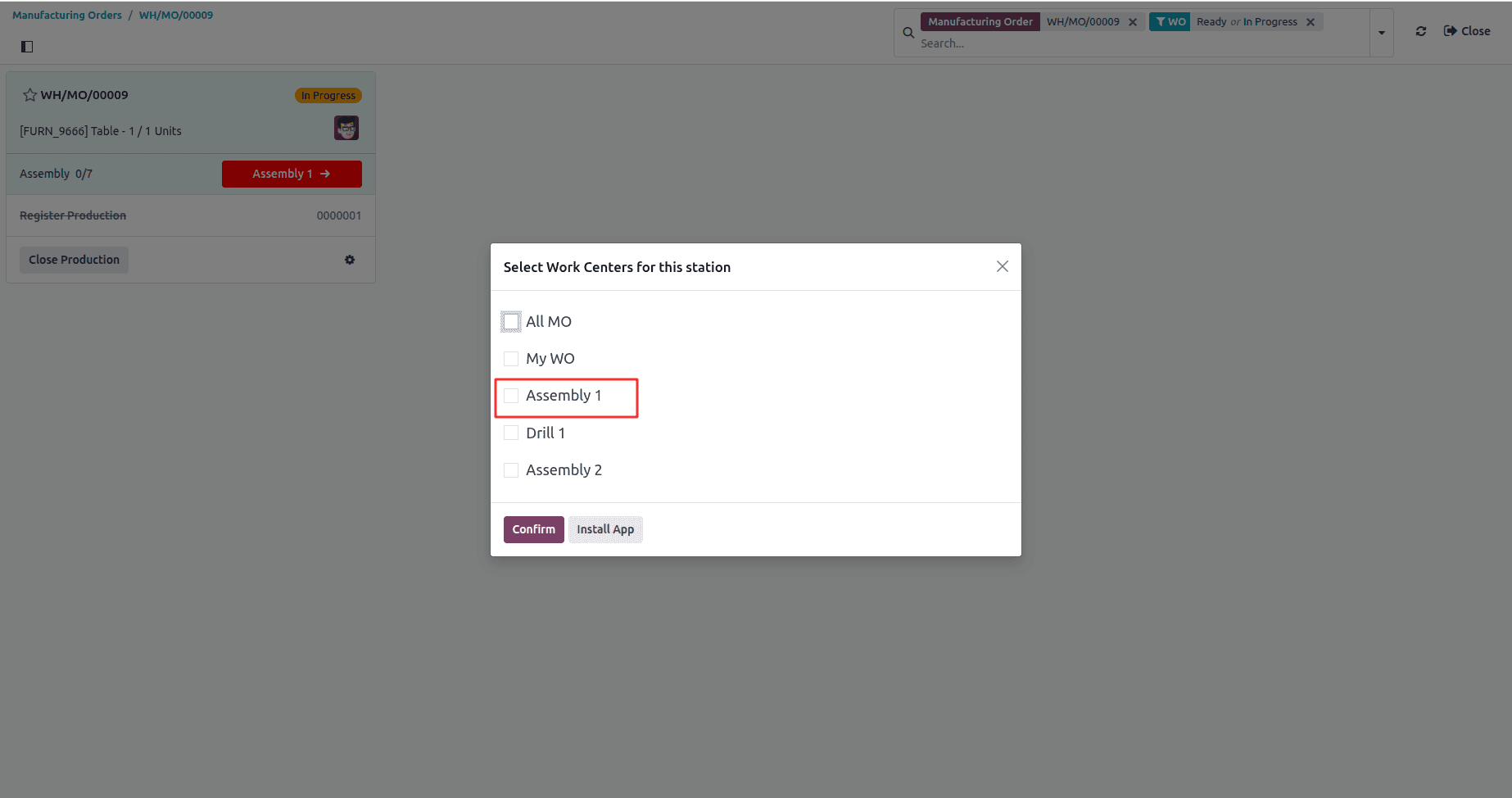

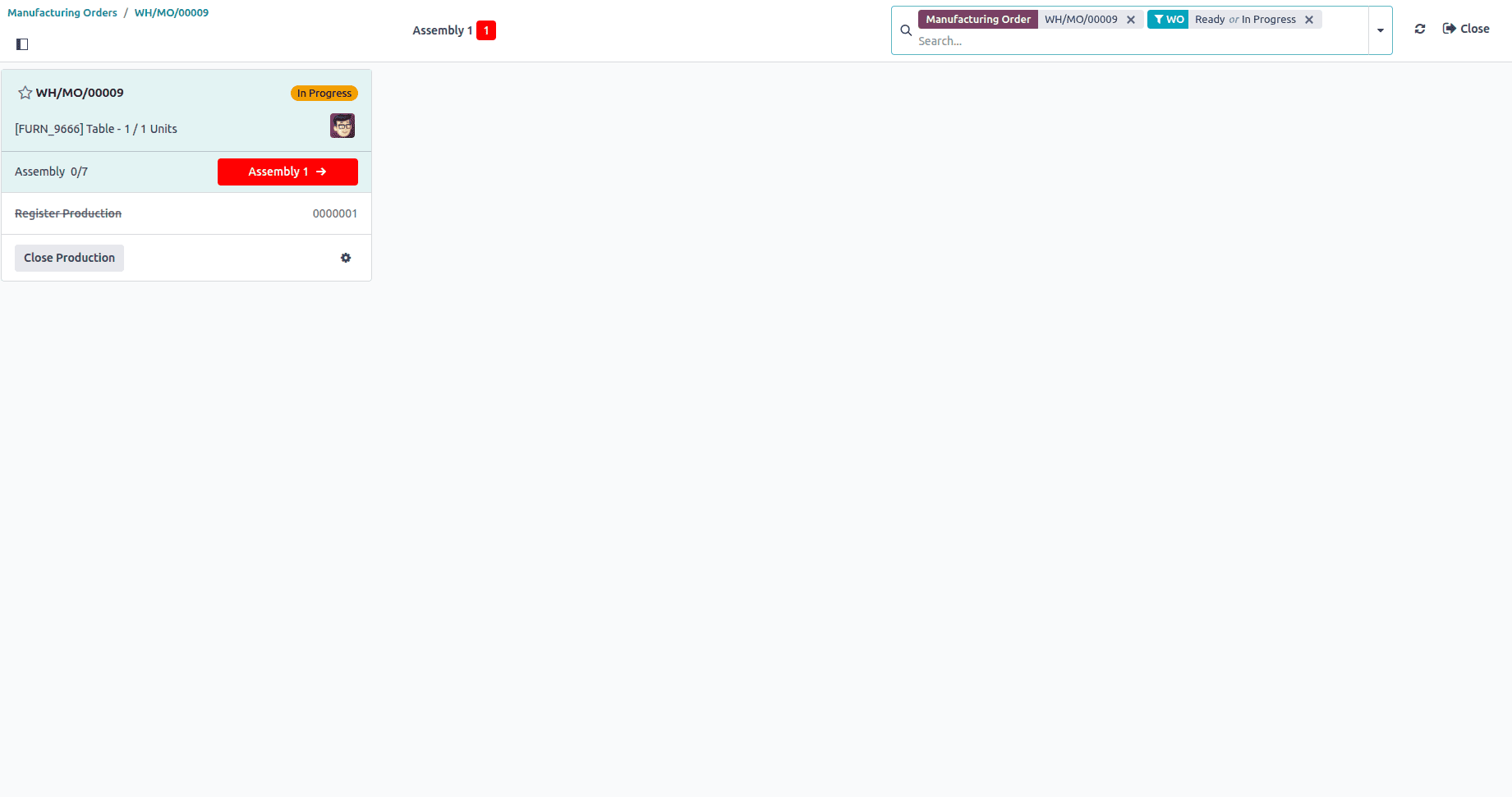

It is the part of the manufacturing workflow where a user is selecting which work centers should be associated with a particular manufacturing station. The "Assembly 1" work center is currently selected, which aligns with the manufacturing order, showing it needs to complete assembly operations (0/7 assemblies completed). This is a typical step in Odoo's manufacturing module for organizing production workflow across different work stations.

Once a work center is selected, the corresponding work instructions become visible, guiding the operator through the assigned task.

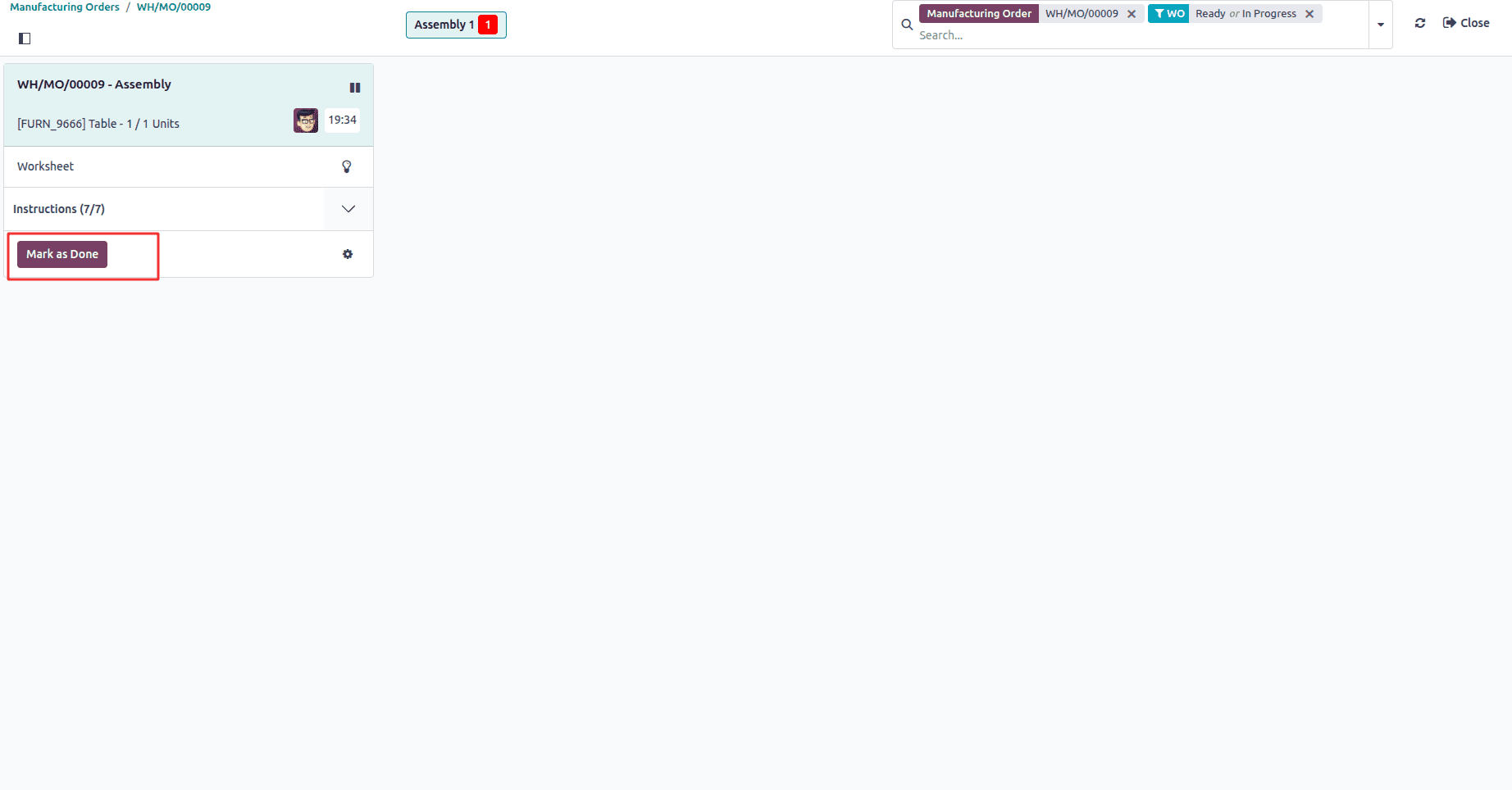

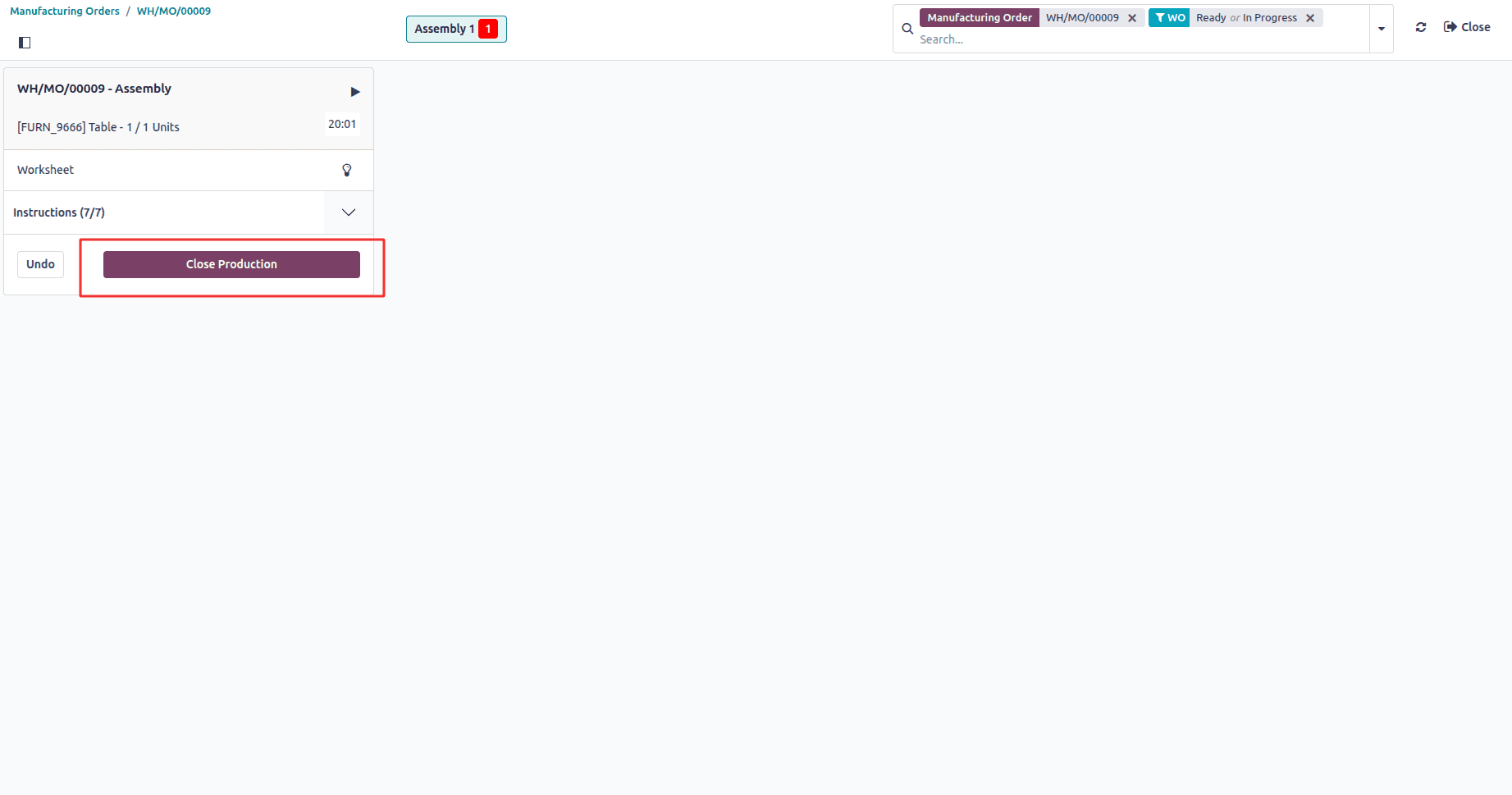

After completing all the instructions, the system will display the "Mark as Done" button to finalize the operation.

After completing all operations, the production order can be closed.

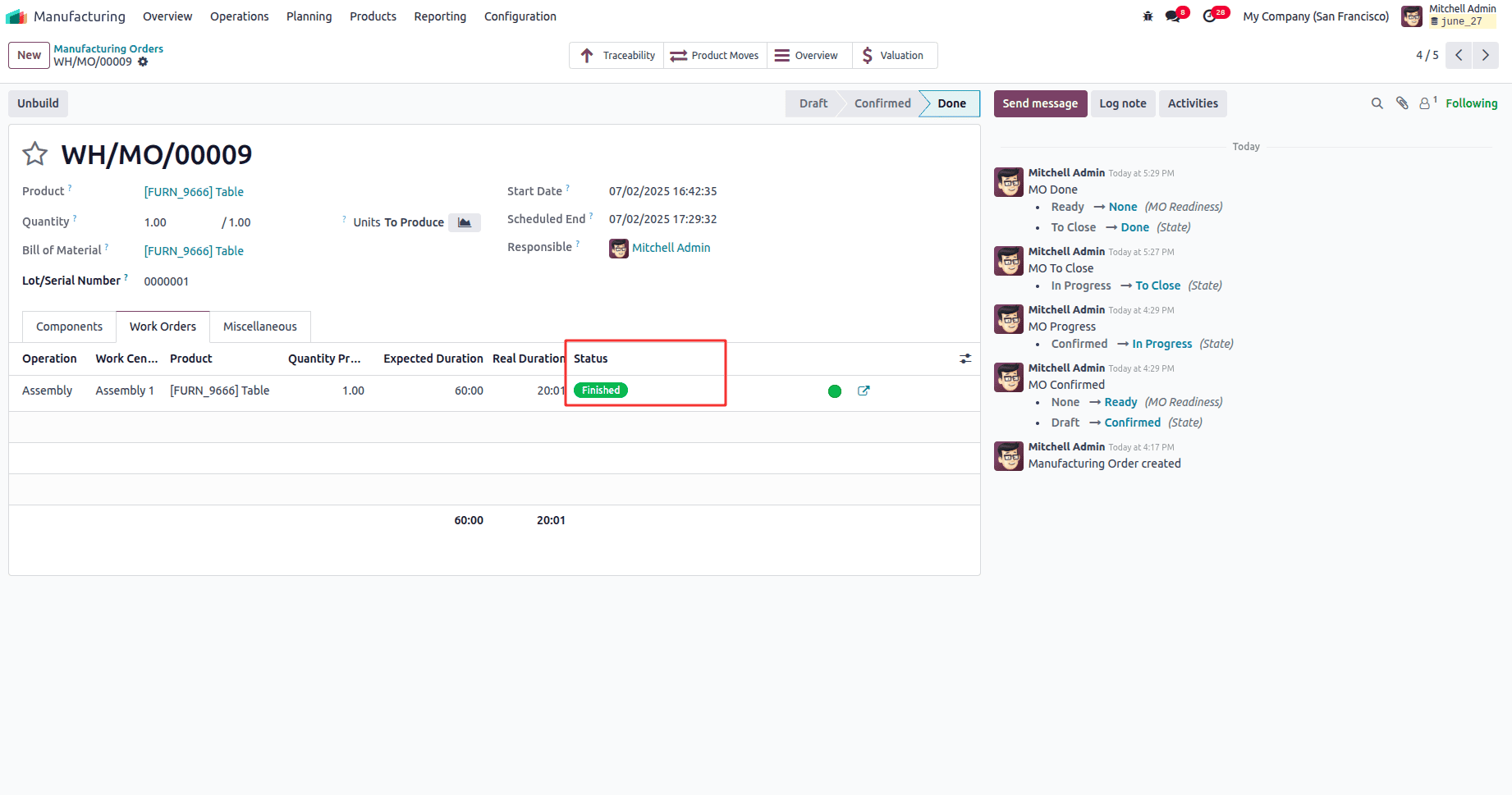

Once all work orders are completed and the final product is transferred to stock, the status of the Manufacturing Order is automatically updated to “Finished,” indicating that the production process has been successfully completed.

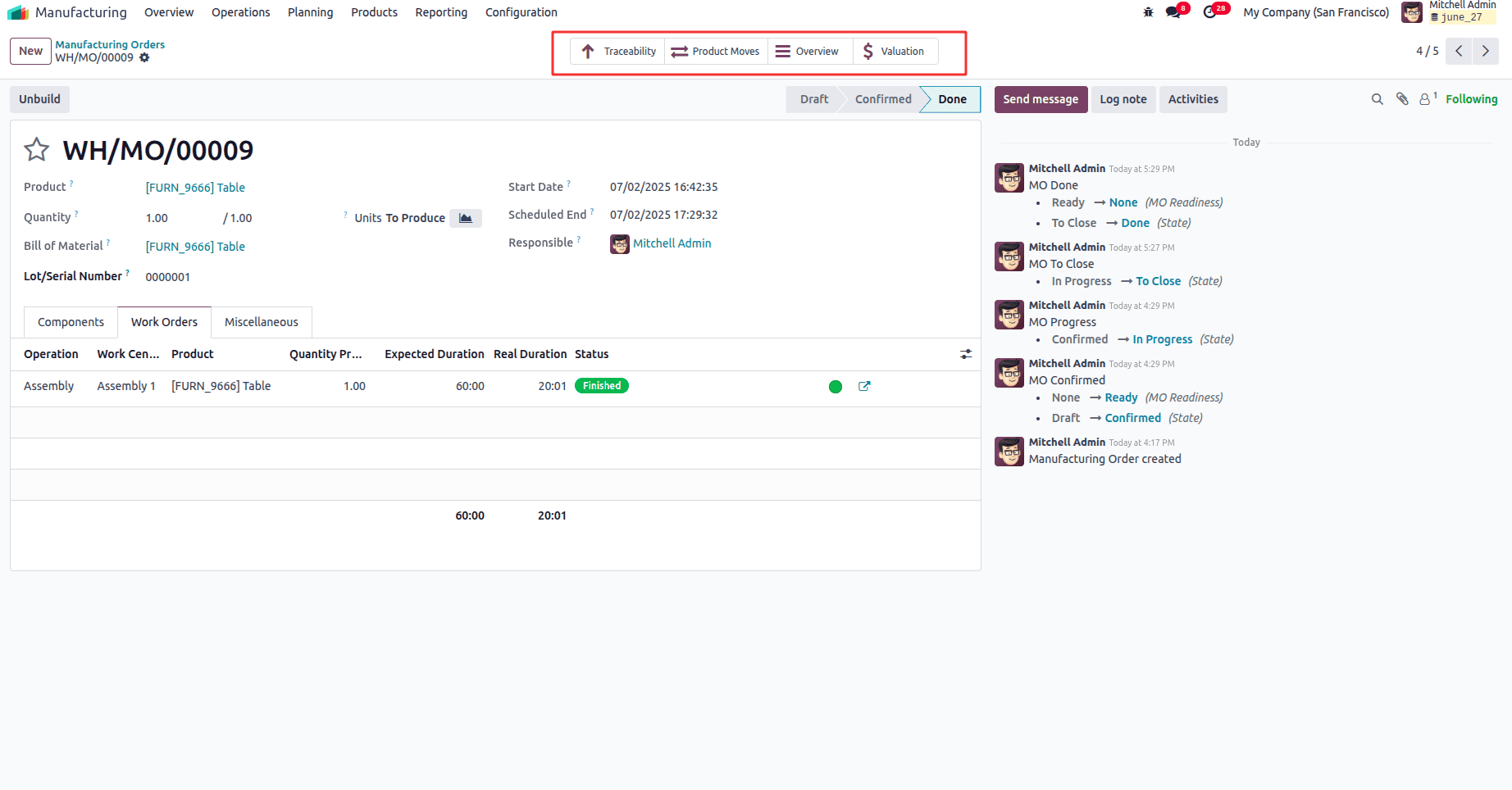

We can observe the smart buttons available for the Manufacturing Order (MO).

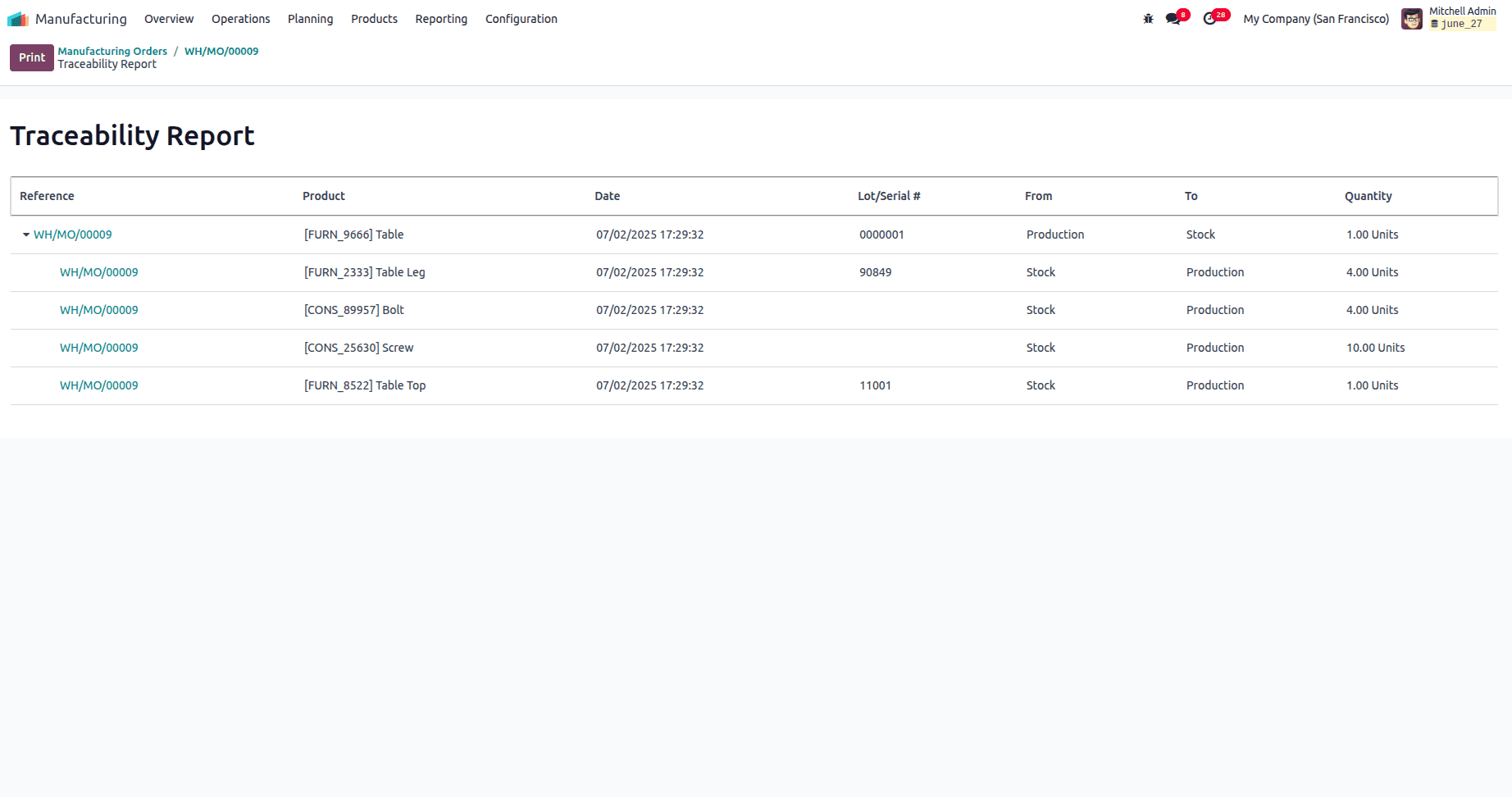

The Traceability smart button provides complete visibility into the manufacturing order's supply chain, showing how raw materials flow into finished products and tracking serial numbers or lot numbers throughout the process, which is essential for quality control and regulatory compliance.

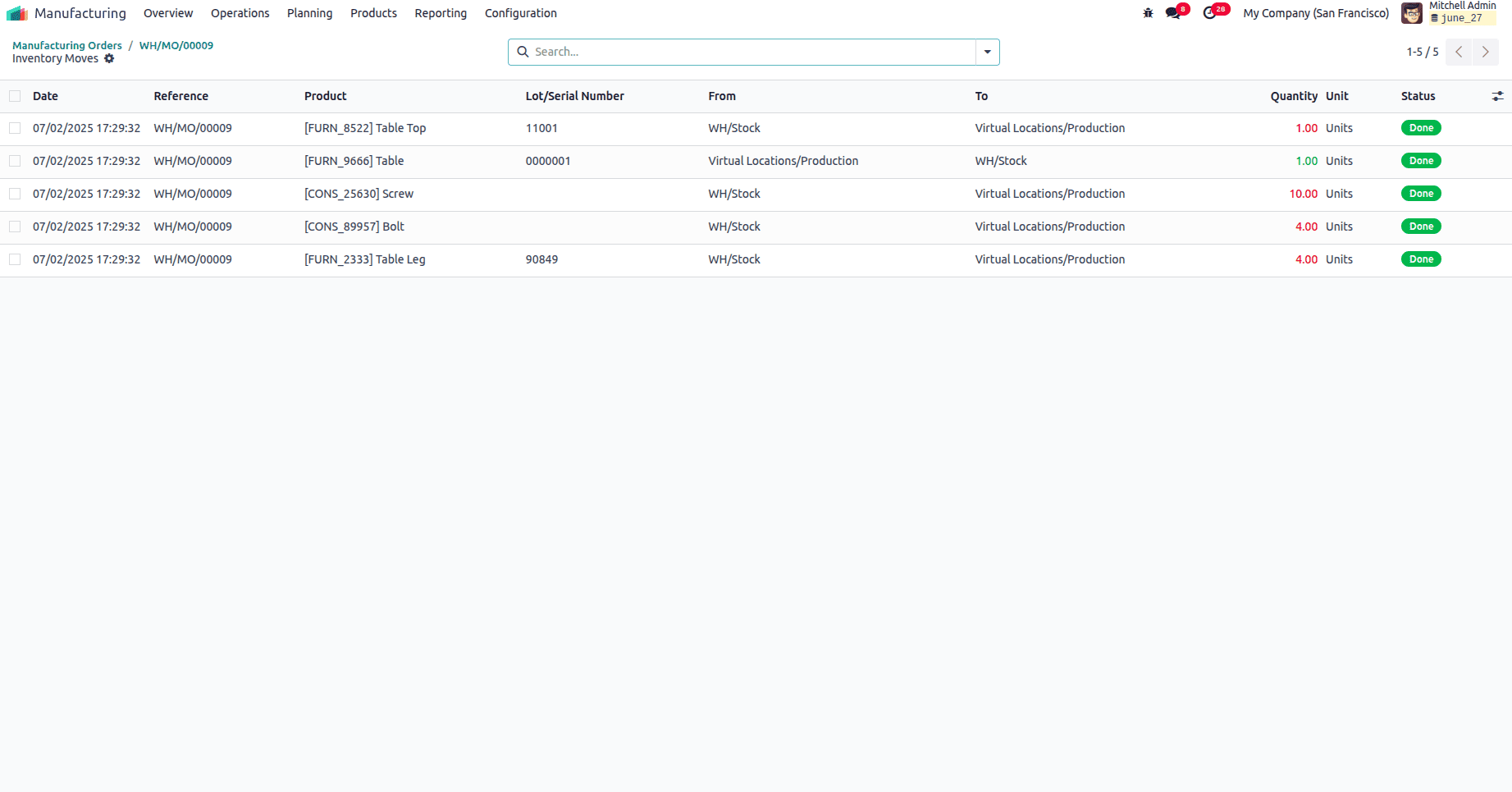

The Product Moves smart button displays all inventory movements that are directly related to this specific manufacturing order. It shows the consumption of raw materials from inventory as well as the creation of finished products during the manufacturing process. This feature also tracks all stock transfers that occur between different warehouse locations throughout the production workflow, providing complete visibility into how materials flow through the manufacturing operation.

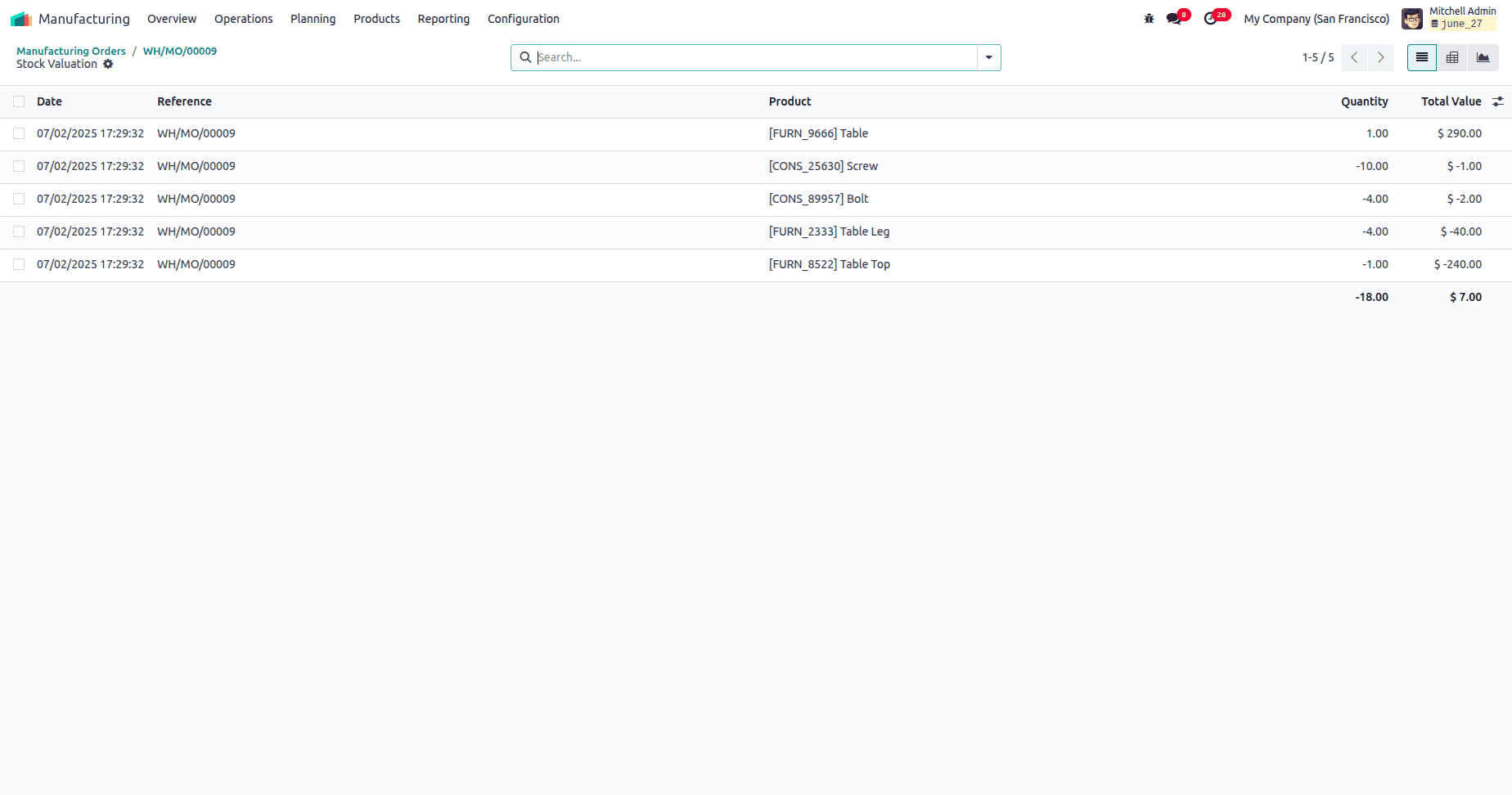

The Valuation smart button shows the financial valuation and costing information for the manufacturing order. It displays a detailed cost breakdown including materials, labor, and overhead expenses. This feature tracks actual costs versus planned costs for the production, helping managers monitor budget performance and profitability.

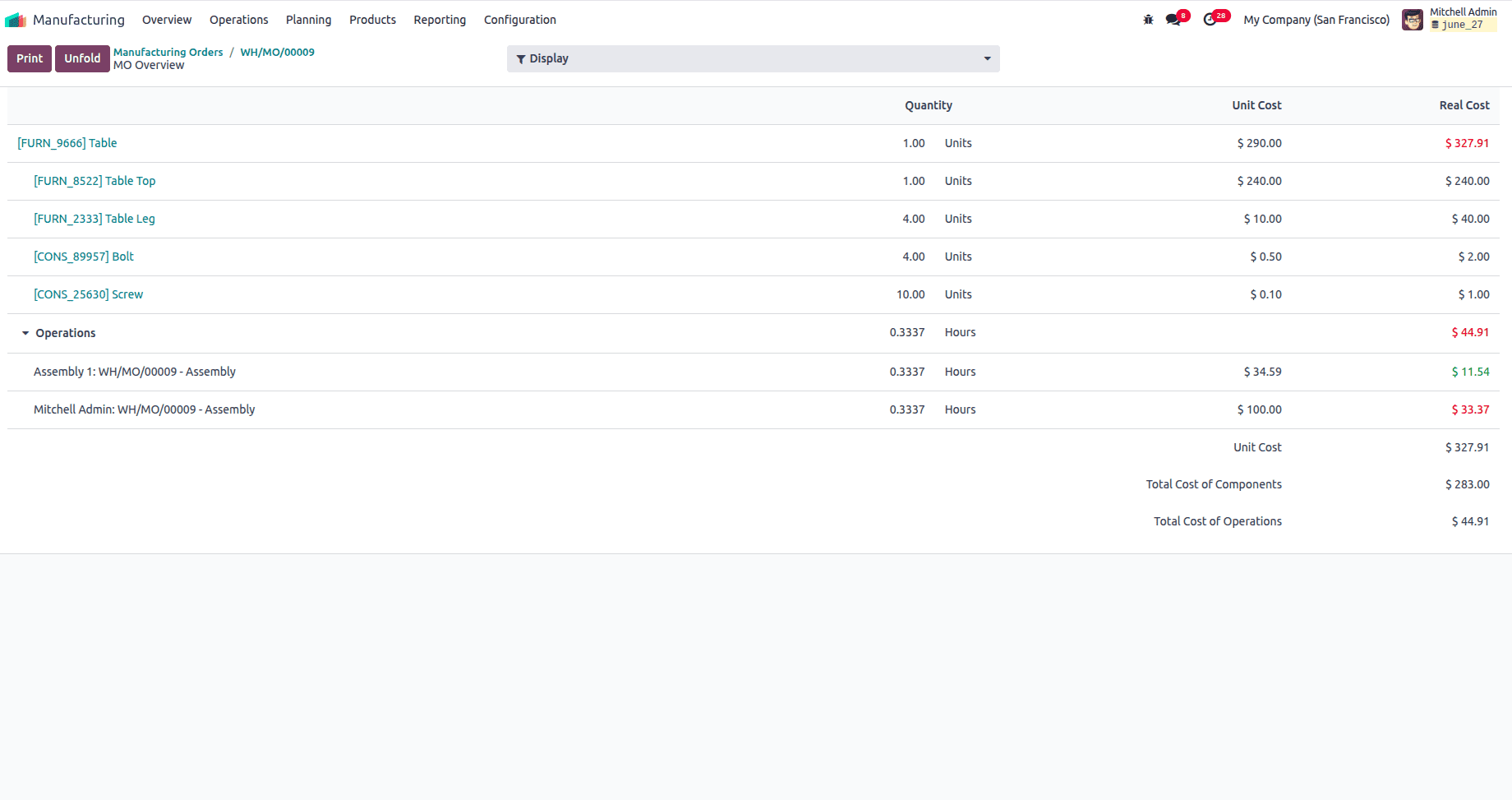

The key features of this MO Overview include cost variance analysis that shows planned vs actual costs with green indicators for budget compliance, detailed component tracking that itemizes every material used with quantities and costs, labor cost breakdown displaying time spent and hourly rates for different operators, and print/unfold options for generating reports or expanding details, making this overview essential for production managers to analyze manufacturing efficiency, cost control, and profitability of individual manufacturing orders.

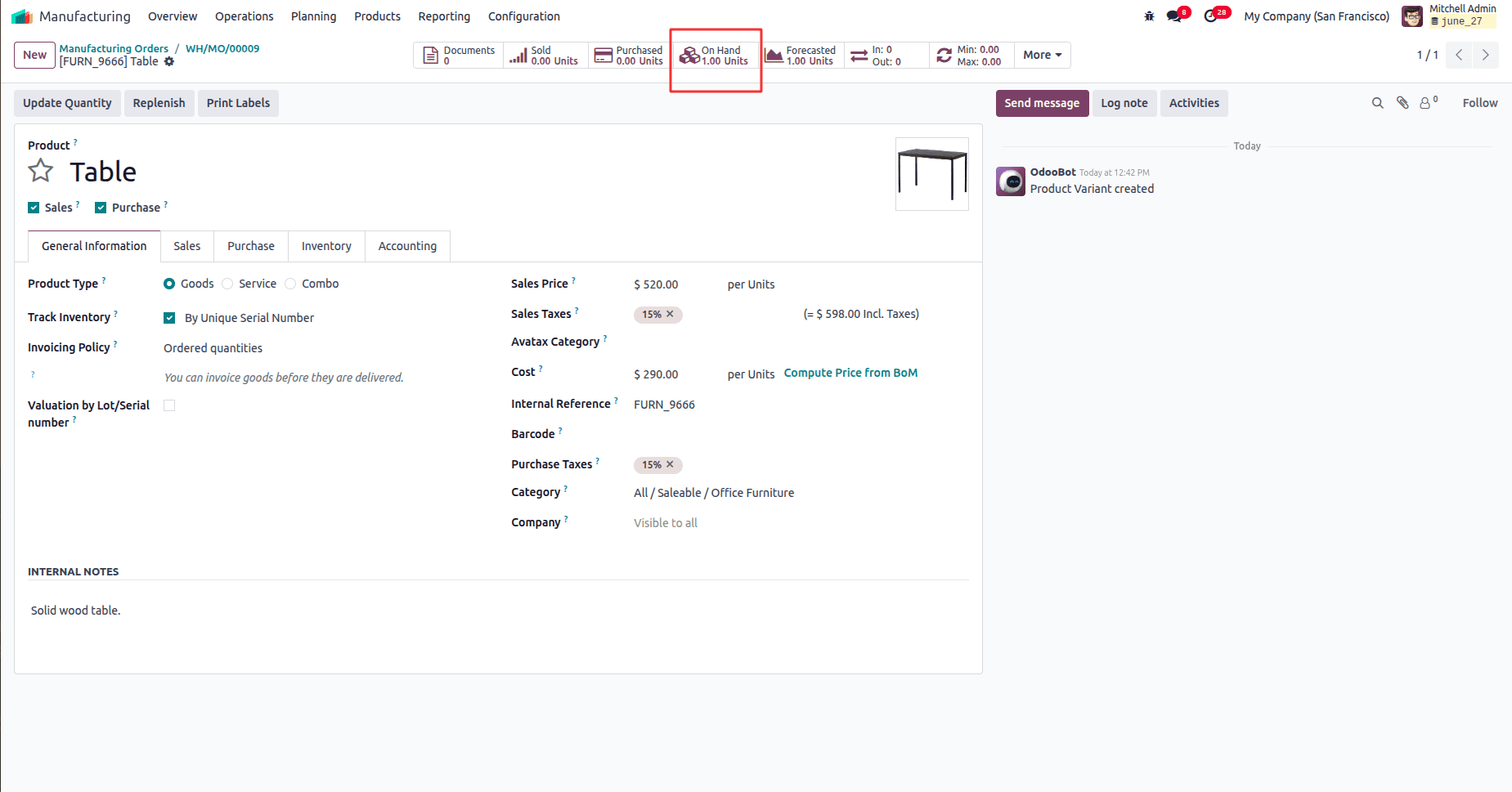

After the completion of manufacturing the Table product, the on-hand quantity will increase by one unit.

The one-step manufacturing configuration in Odoo 18 simplifies the entire production process by combining component consumption and finished goods transfer into a single operation. This approach is ideal for small to mid-sized manufacturers or production environments that require speed, efficiency, and minimal complexity.

The process begins by enabling essential settings like Multi-Step Routes and Storage Locations, configuring the warehouse to use the one-step manufacturing flow, and defining products, Bills of Materials (BoMs), and work centers. Once a Manufacturing Order (MO) is created and confirmed, Odoo automatically reserves materials, schedules operations, and enables real-time tracking via the Work Orders or Shop Floor interface.

Operators can start, pause, or complete each operation directly on the shop floor, with Odoo logging durations and costs. Once all tasks are completed, the system automatically records stock movements, updates inventory, and finalizes the production order, resulting in accurate cost accounting and streamlined manufacturing execution.

To read more about How to Manage Your Manufacturing with Odoo 17 Manufacturing App, refer to our blog How to Manage Your Manufacturing with Odoo 17 Manufacturing App.